Brands

MHM Automation incorporates some of the most respected names in the industries we service.

Brands we own

MHM Automation incorporates some of the most respected names in the industries we service.

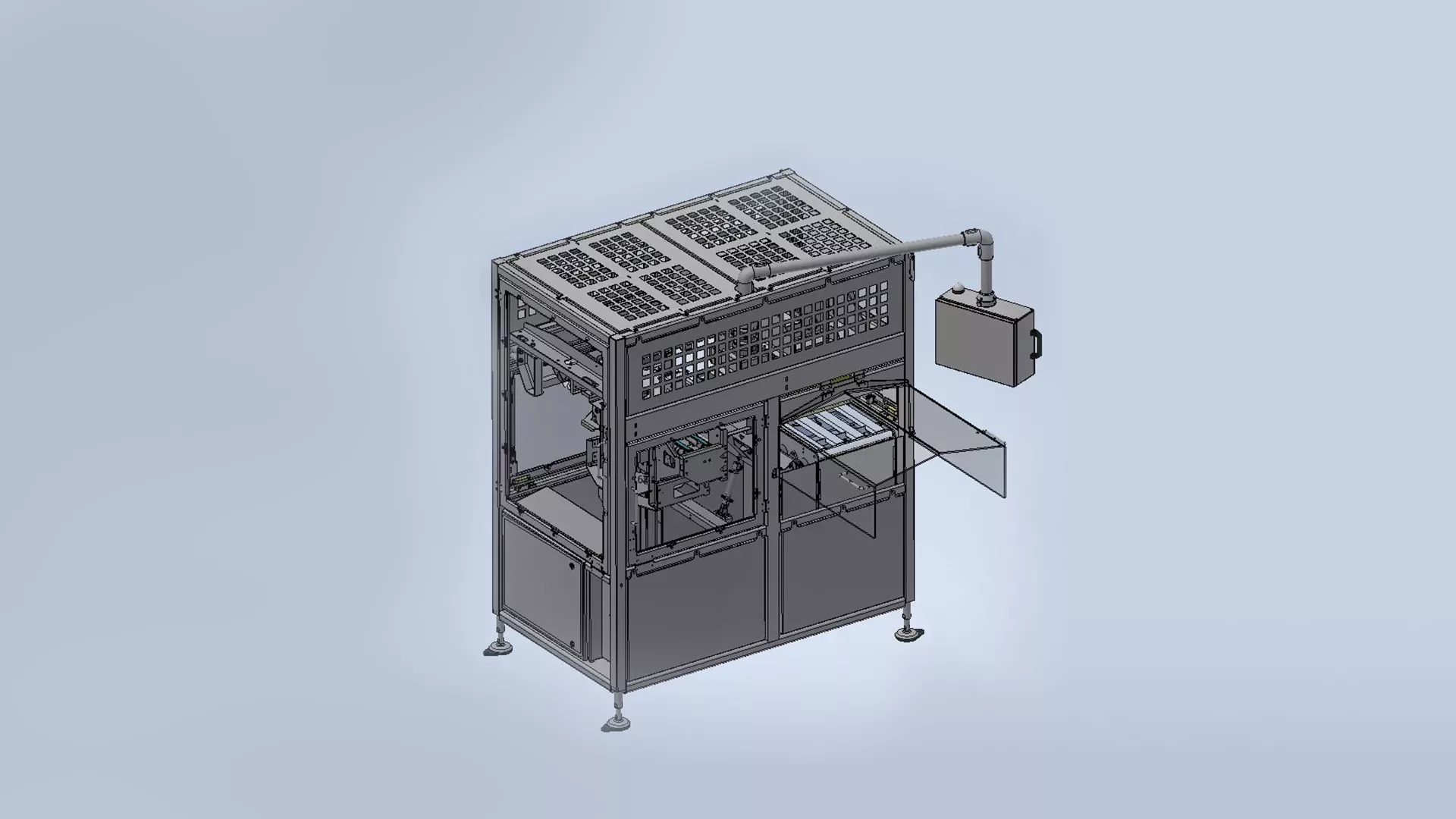

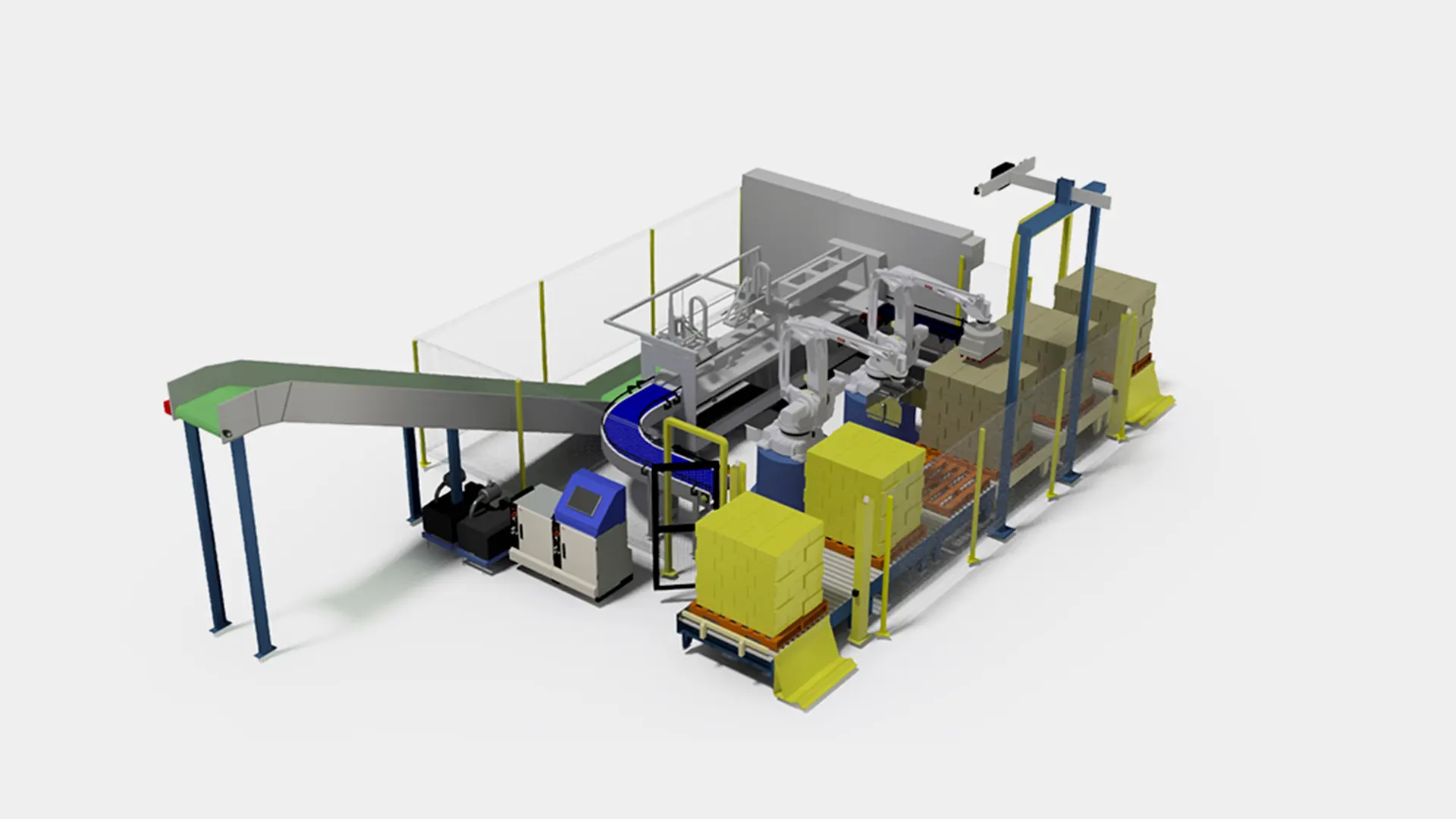

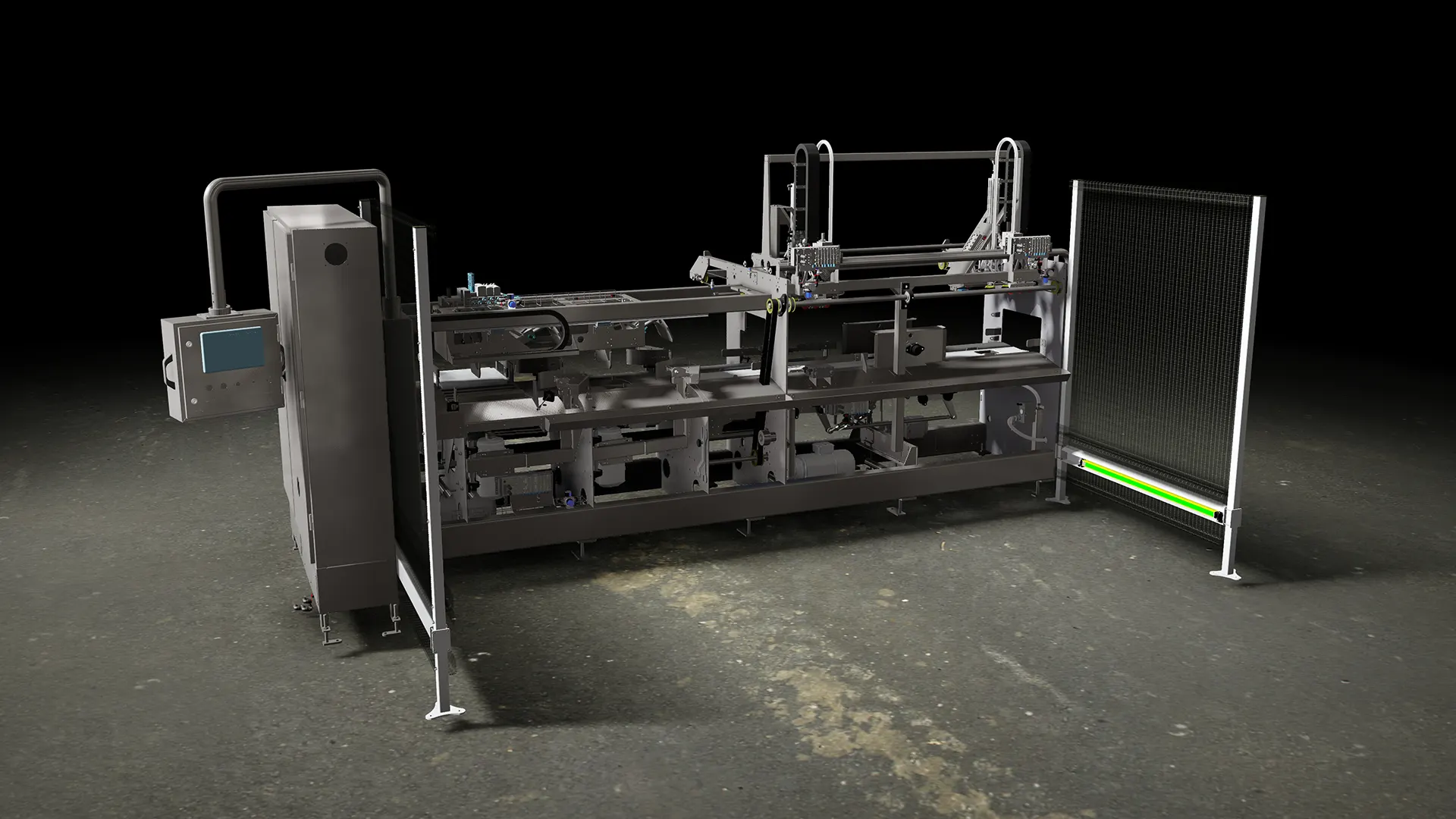

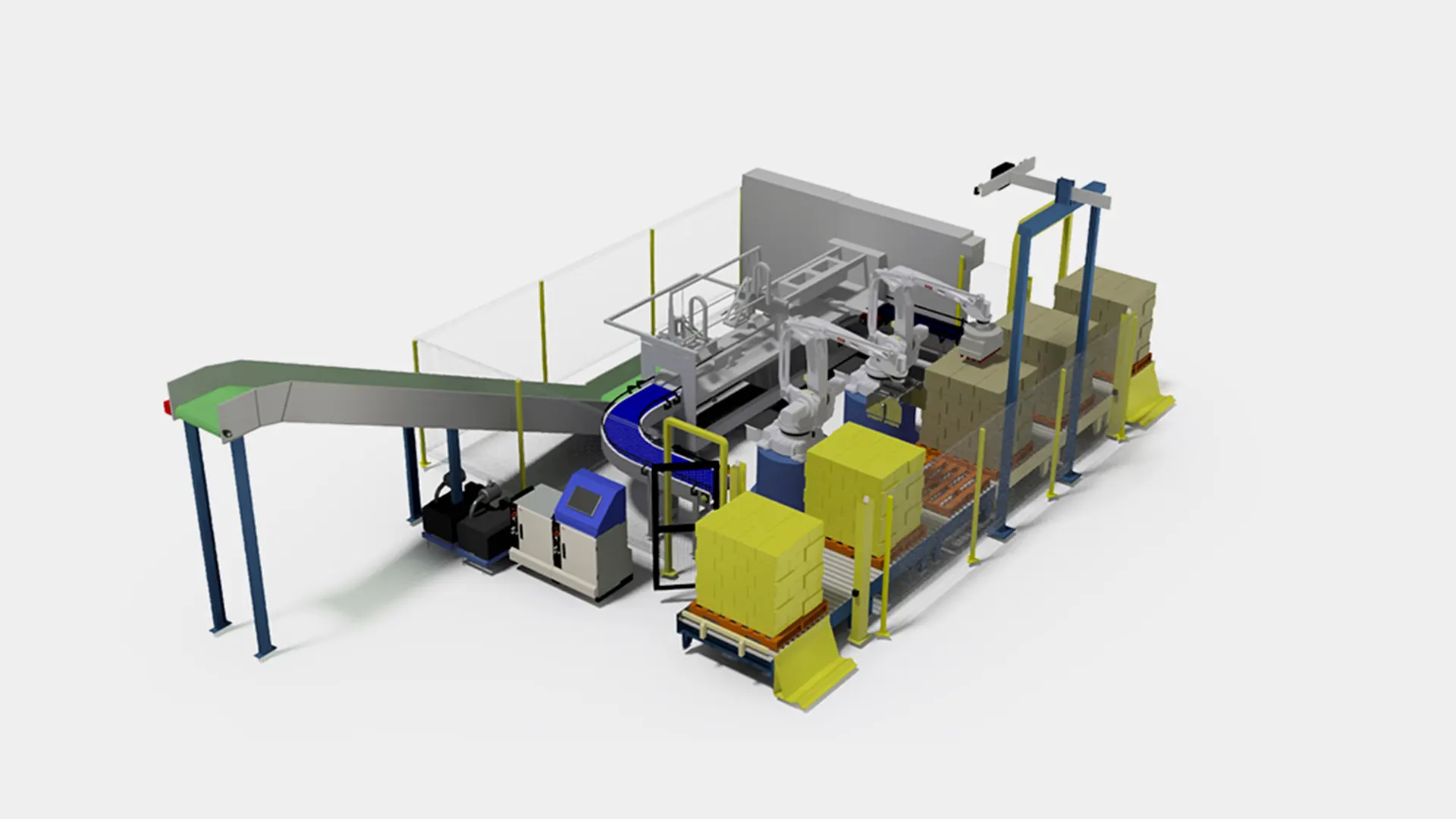

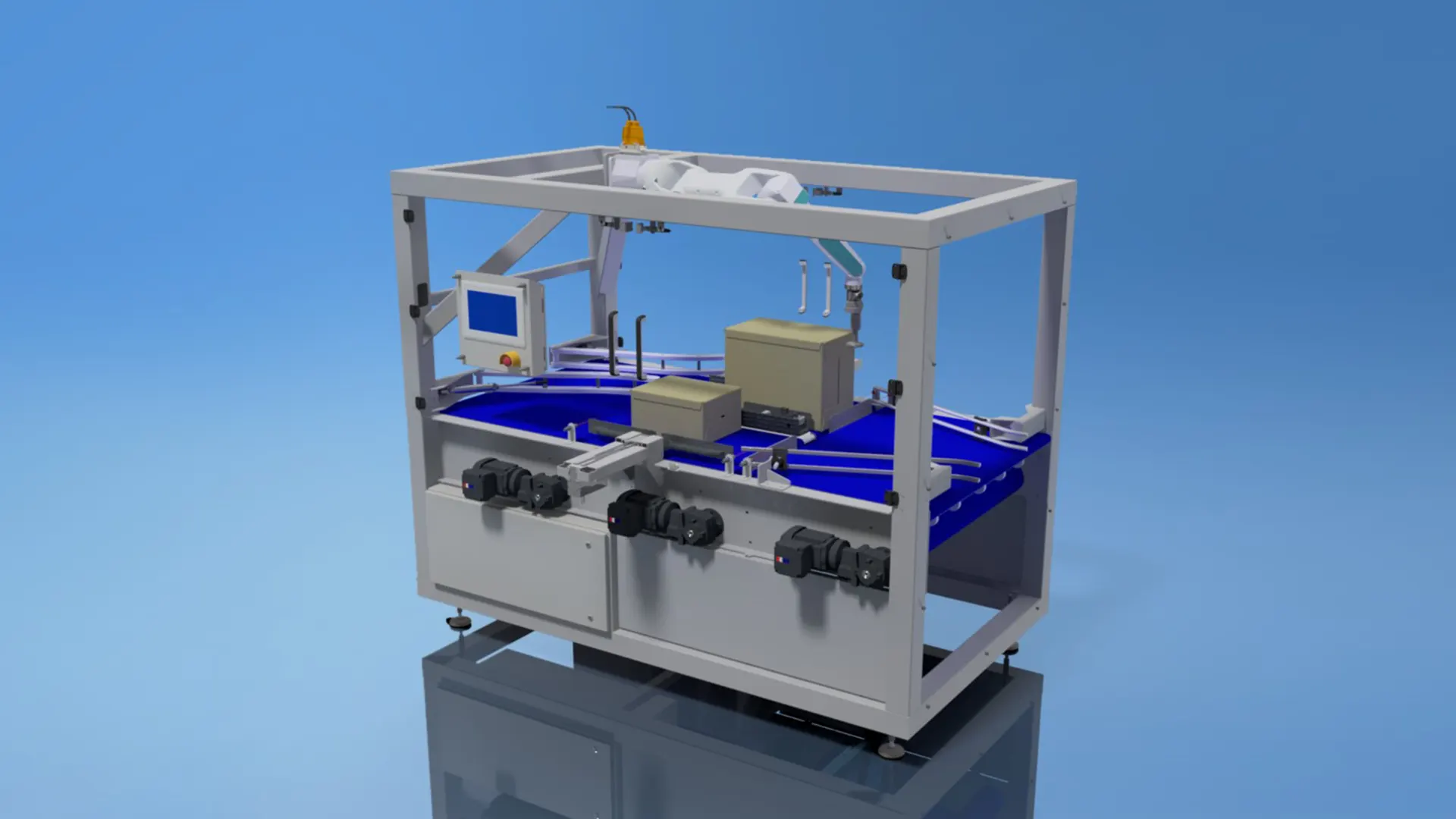

In 1998, we acquired AiCo, a brand with a well-established reputation in the industry, a leader in cartoning and packaging equipment for over 35 years.

AiCo equipment is known for its rugged reliability in tough environments and excellent return on investment.

Our range of carton erectors, stuffers, lidders and closers includes specialised solutions for the meat and horticulture industries. We also provide complete line design and integration.

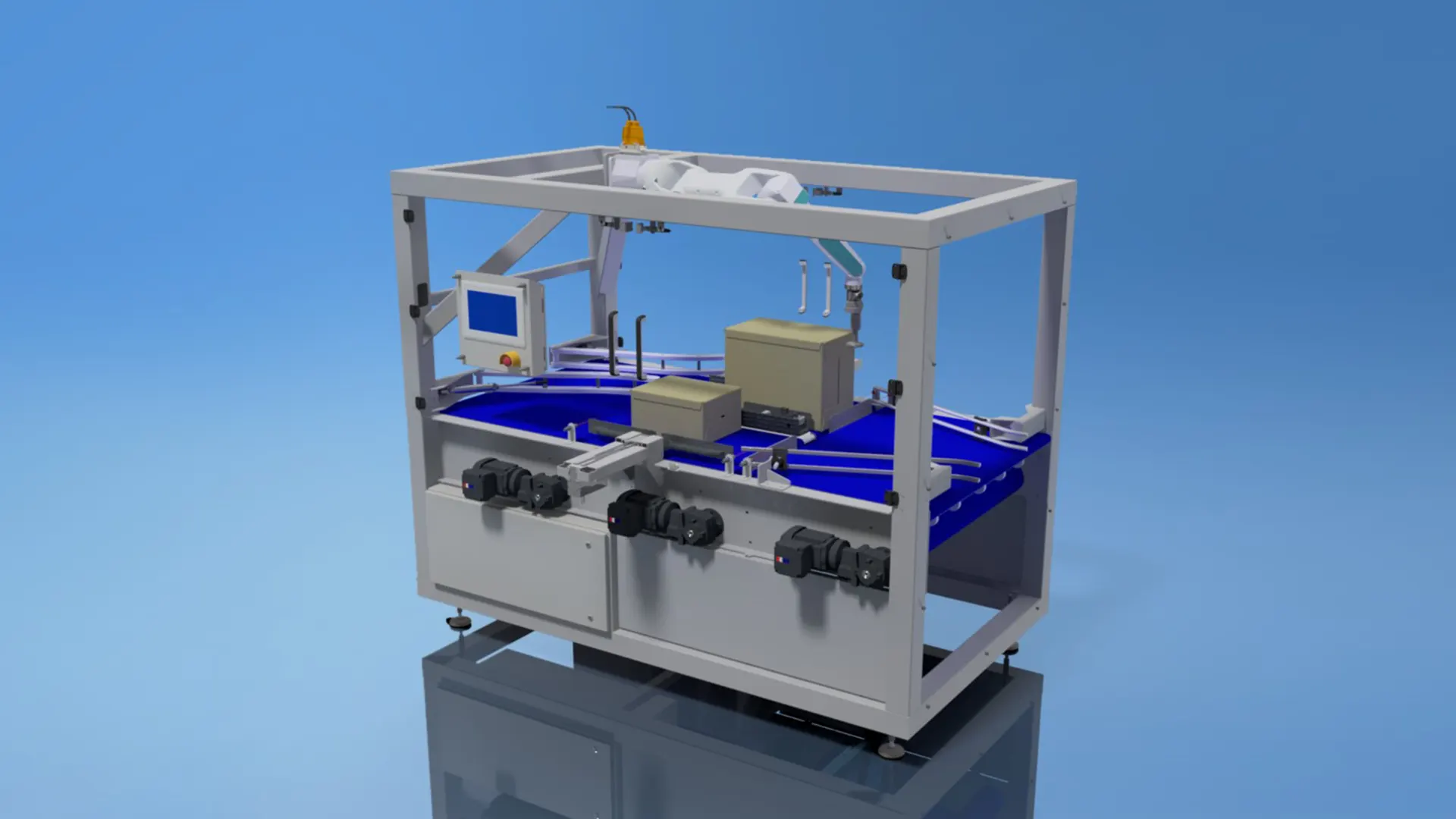

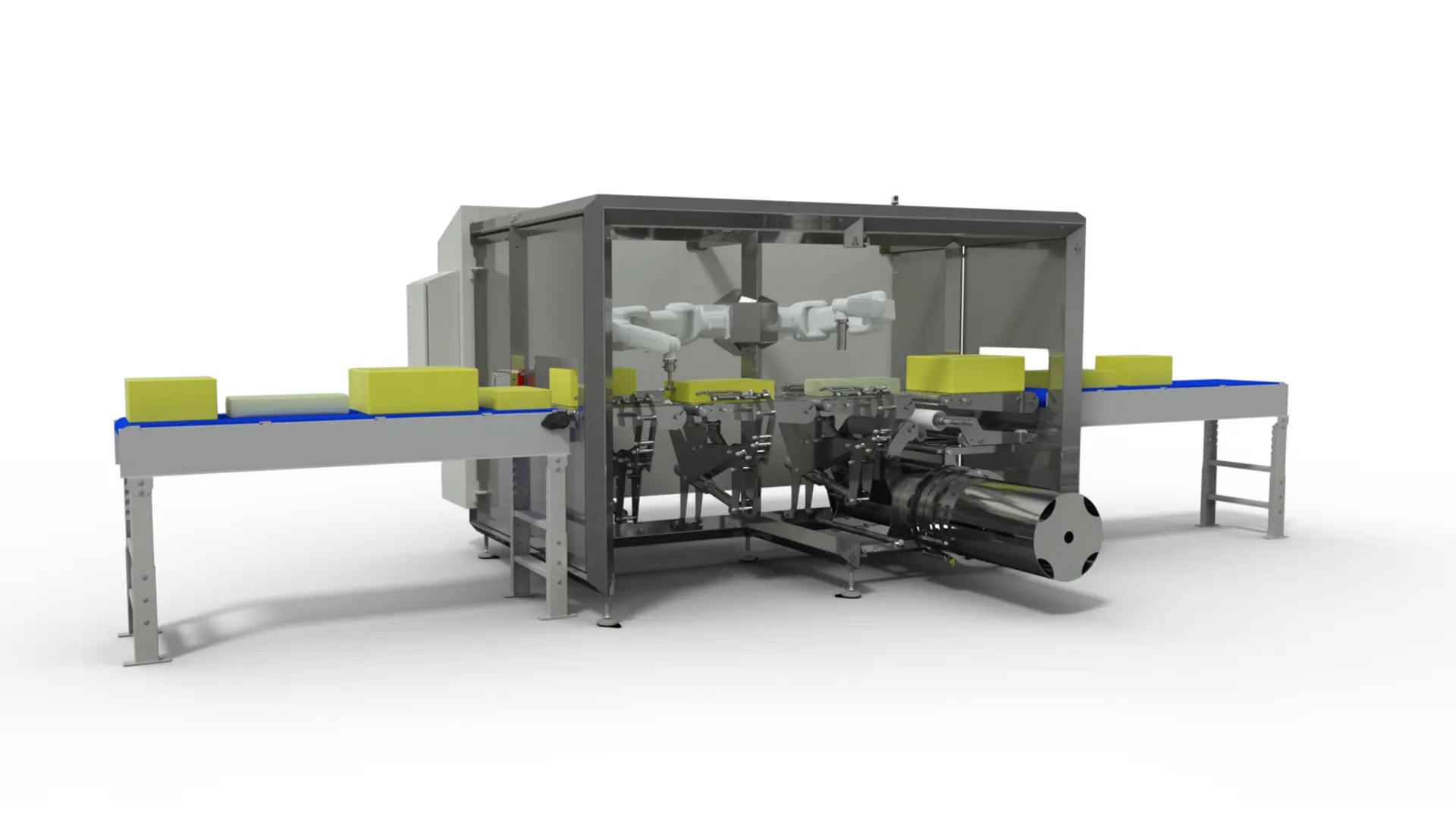

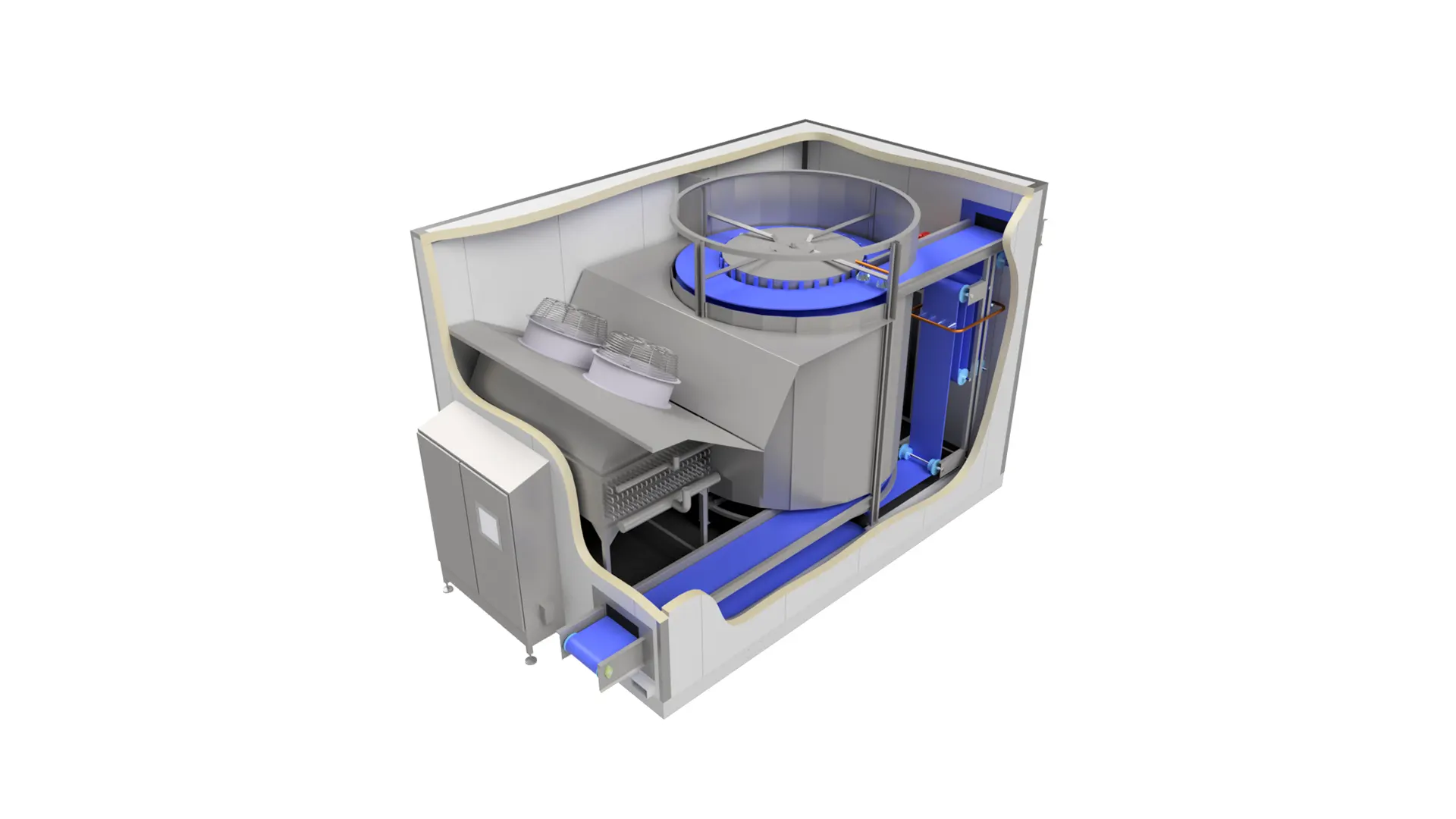

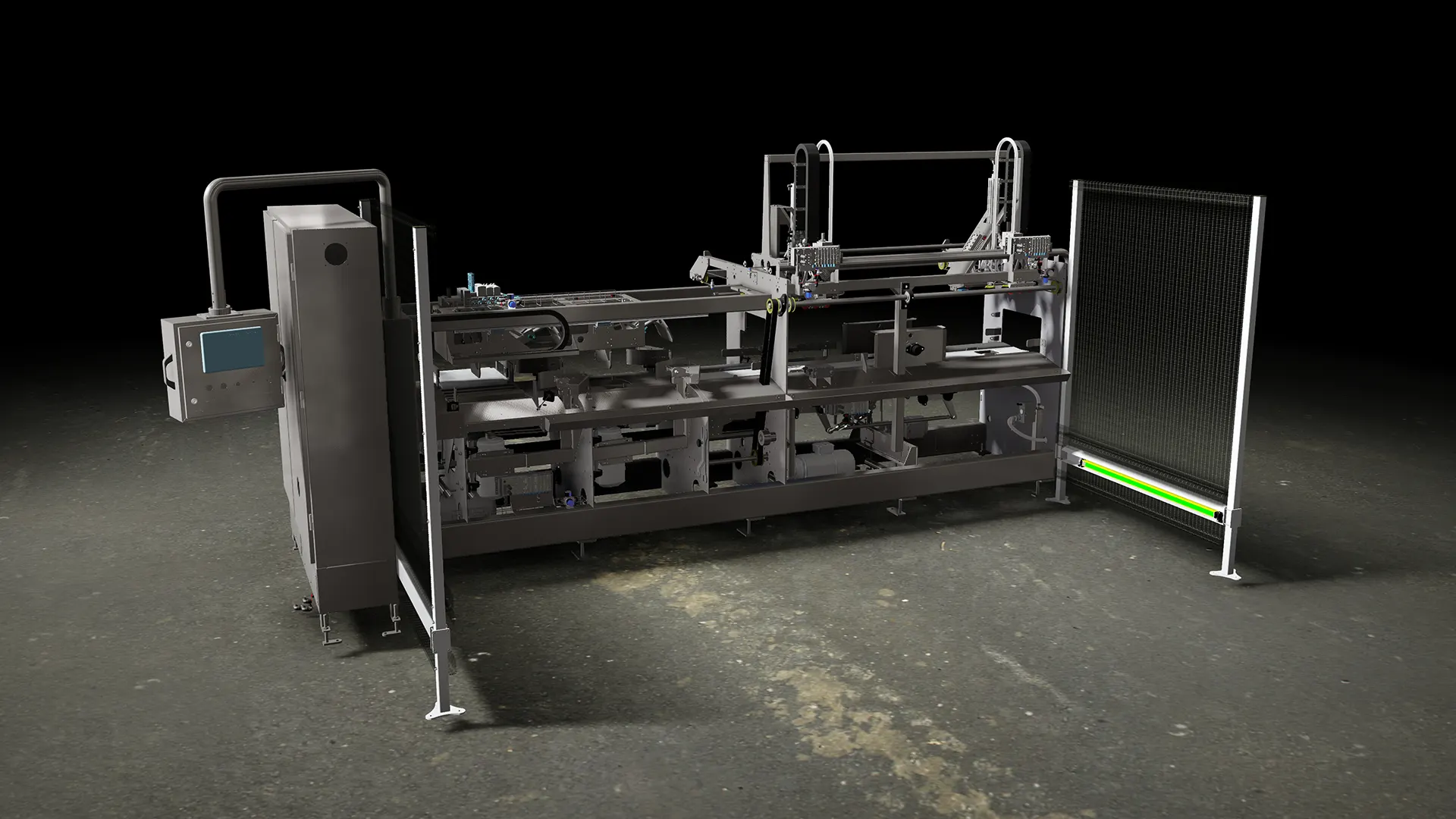

World-renowned as the preferred option for cheese packaging systems, BetaVac was acquired by MHM Automation in 2004.

Hundreds of BetaVac vacuum packaging, testing and turning systems have been installed worldwide for some of the biggest names in dairy.

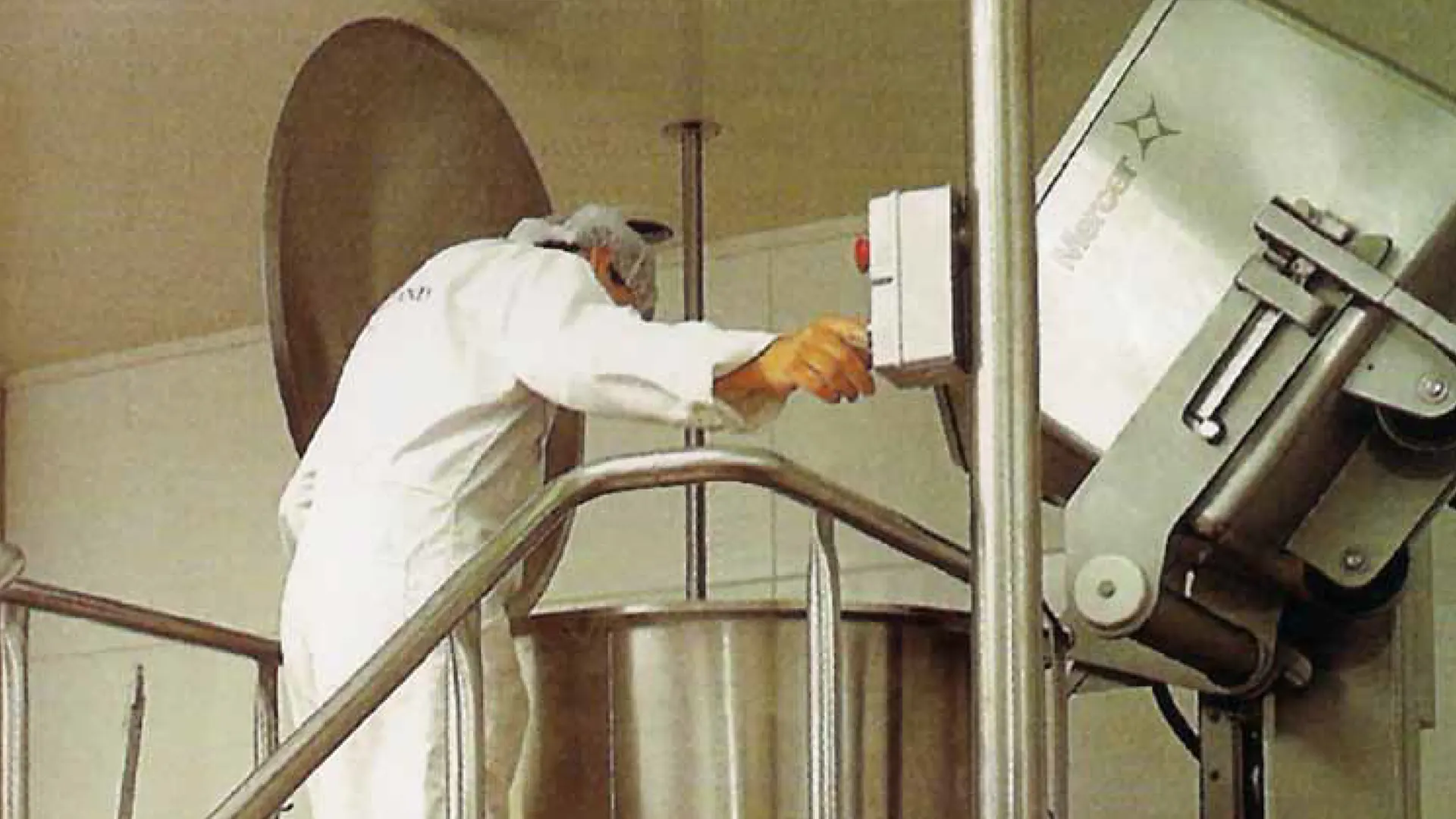

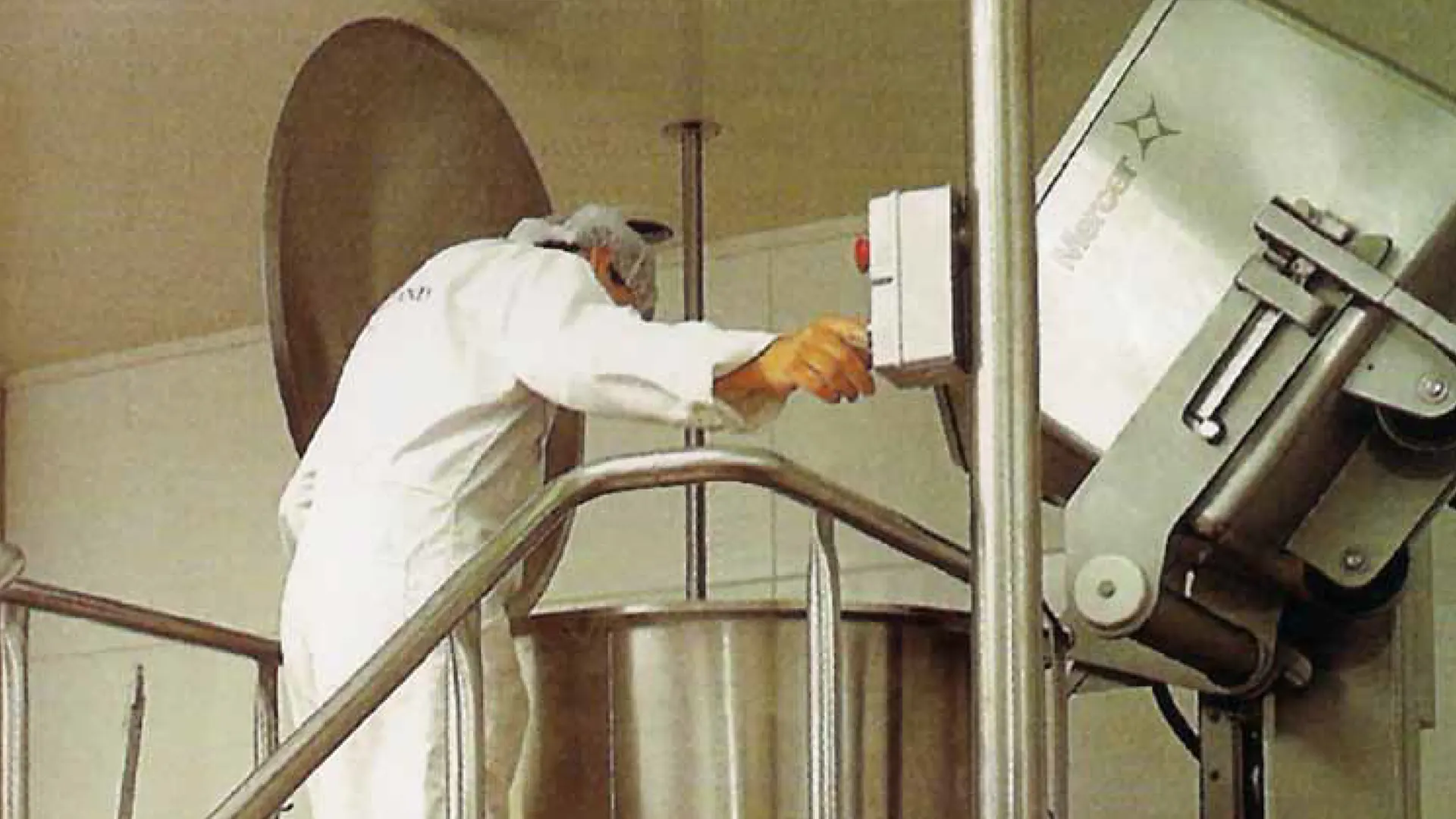

In 2020, we acquired Mercer, a leading name in the stainless steel fabrication industry.

We specialise in the design and manufacture of plant and equipment for the dairy, wine and food processing sectors in New Zealand and Australia.

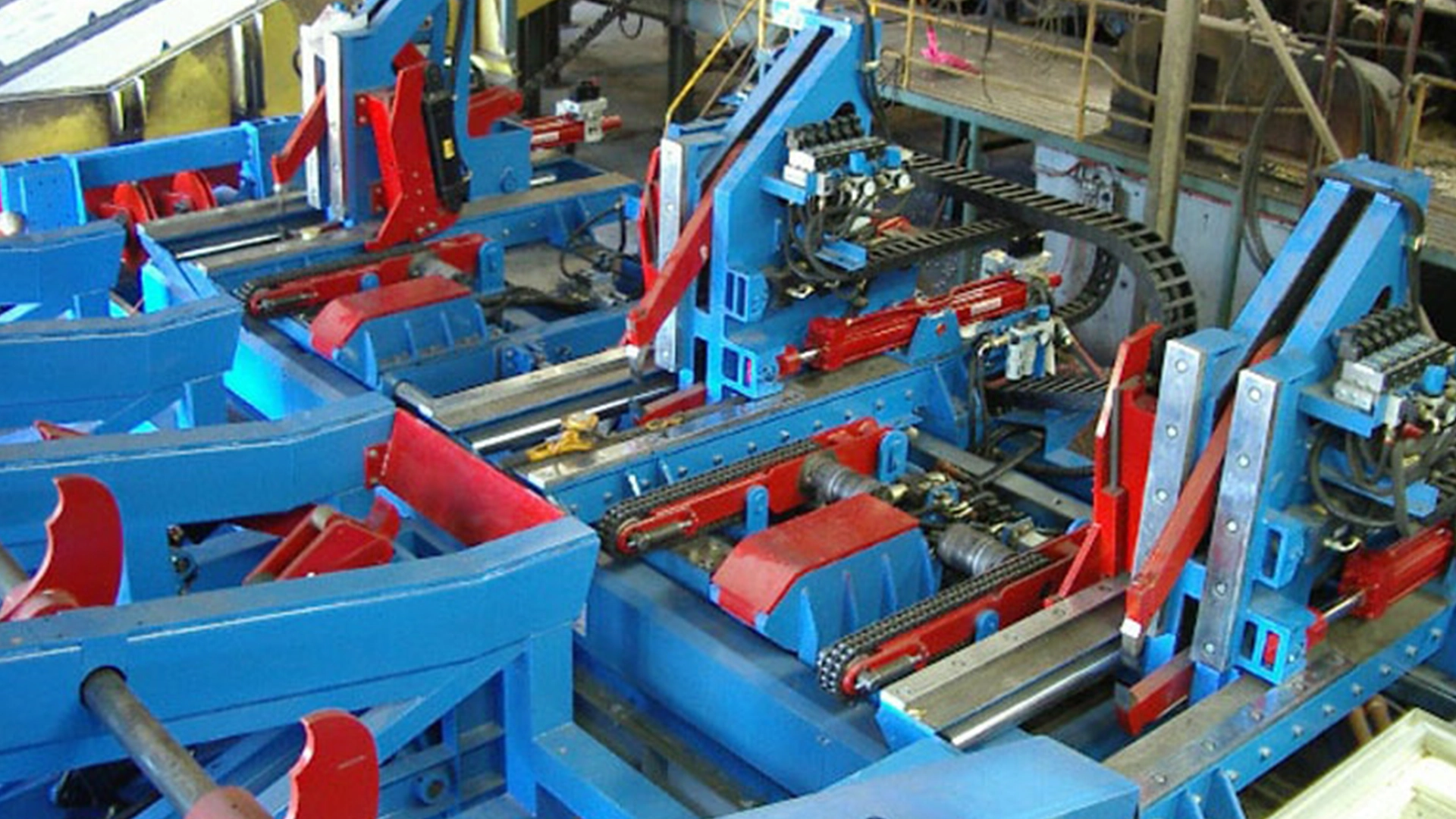

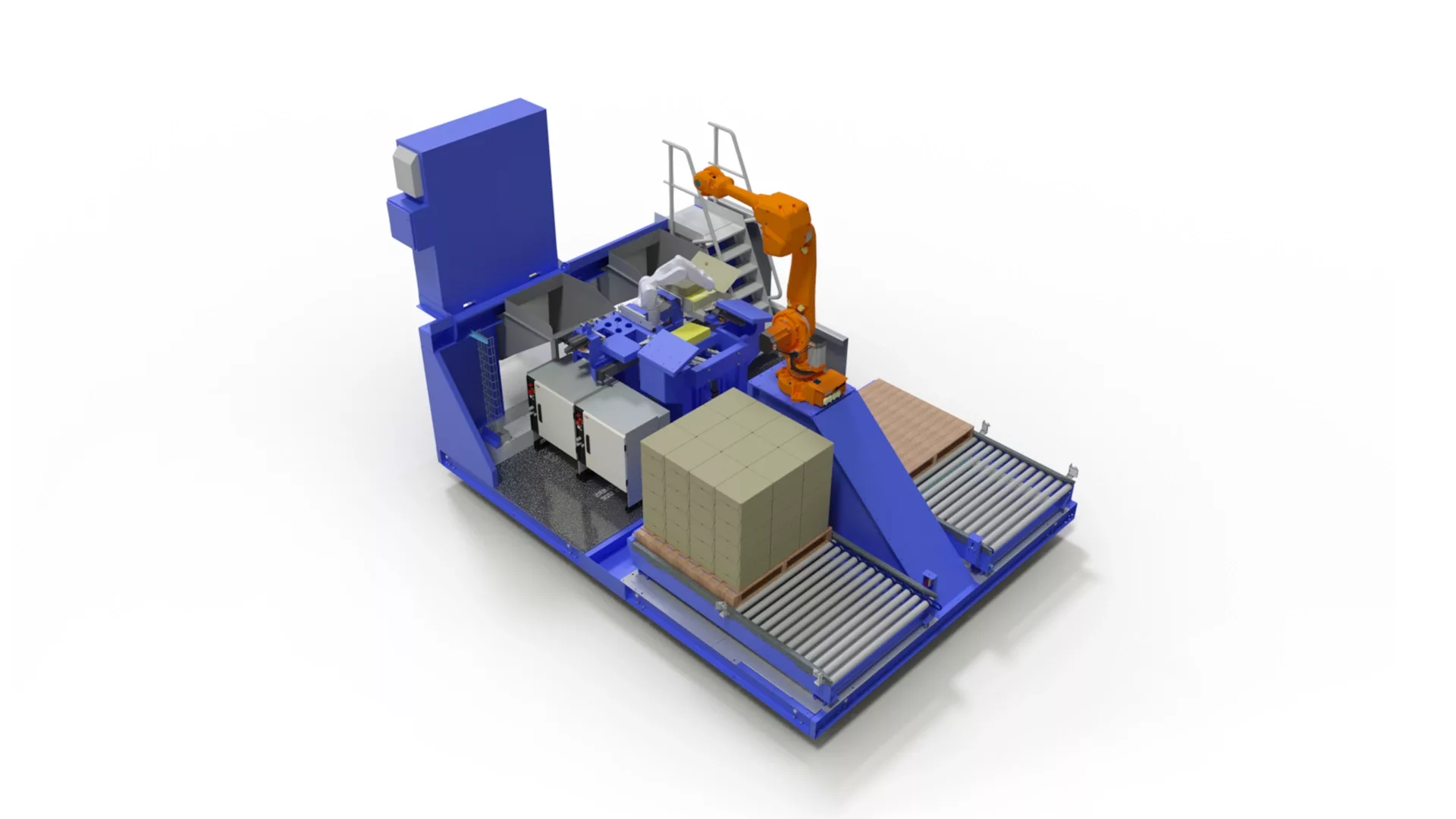

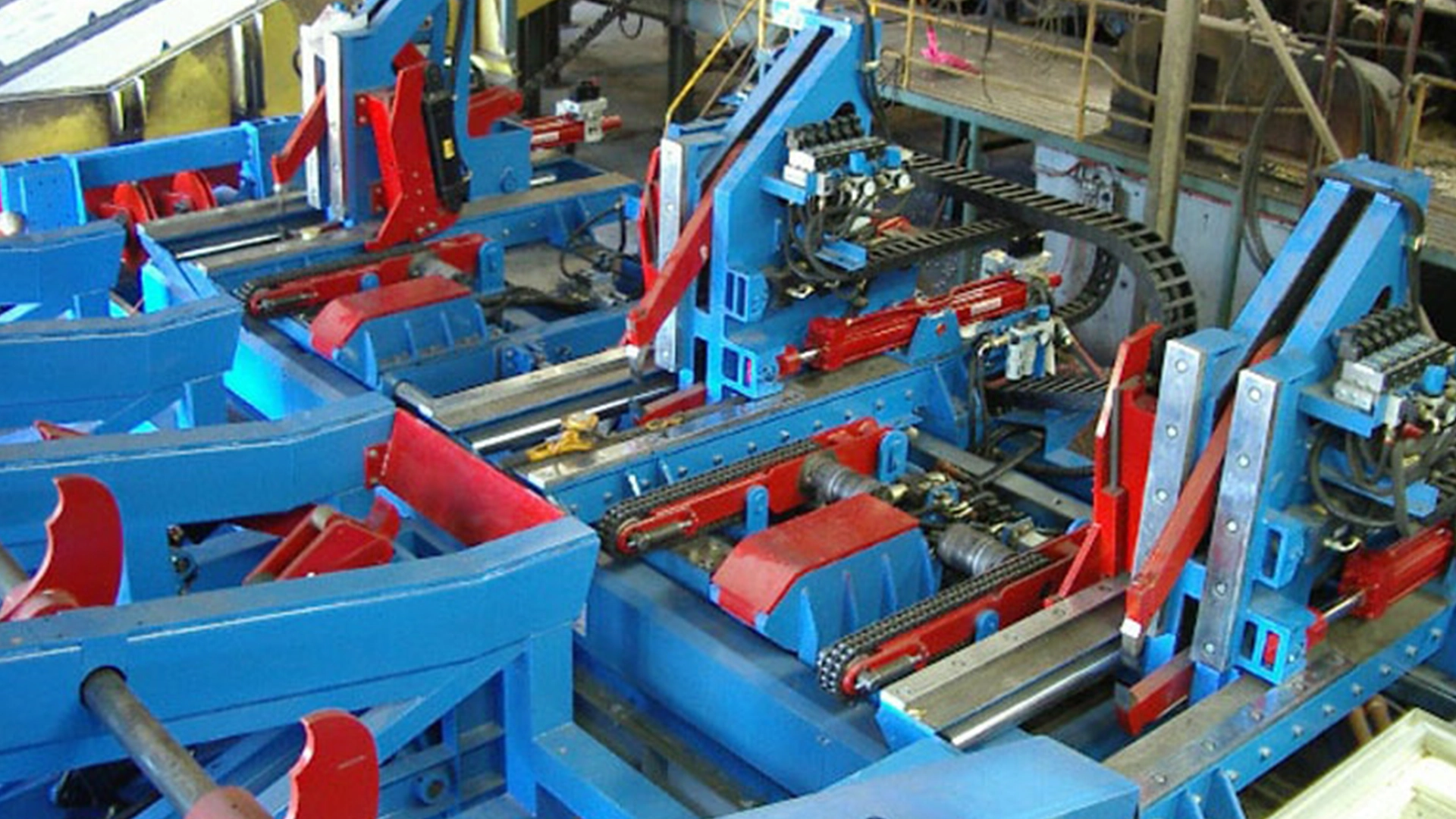

Recognised as a world leader in automated reverse packaging and product handling systems, we acquired Haden & Custance (H&C) in 2016.

While many other companies provide solutions to putting product into packaging, we are specialists in removing packaging from product ready for further processing.

Our technologies were developed for the cheese processing and cheese conversion operations but have since been applied to meat processing and e-commerce fulfilment.

H&C equipment is renowned for being robust, reliable and simple to operate, as well as providing an excellent return on investment.

All of our equipment can be provided as standalone machines or as part of a complete process solution. We have particular expertise in the integration of these automated systems into existing process lines.

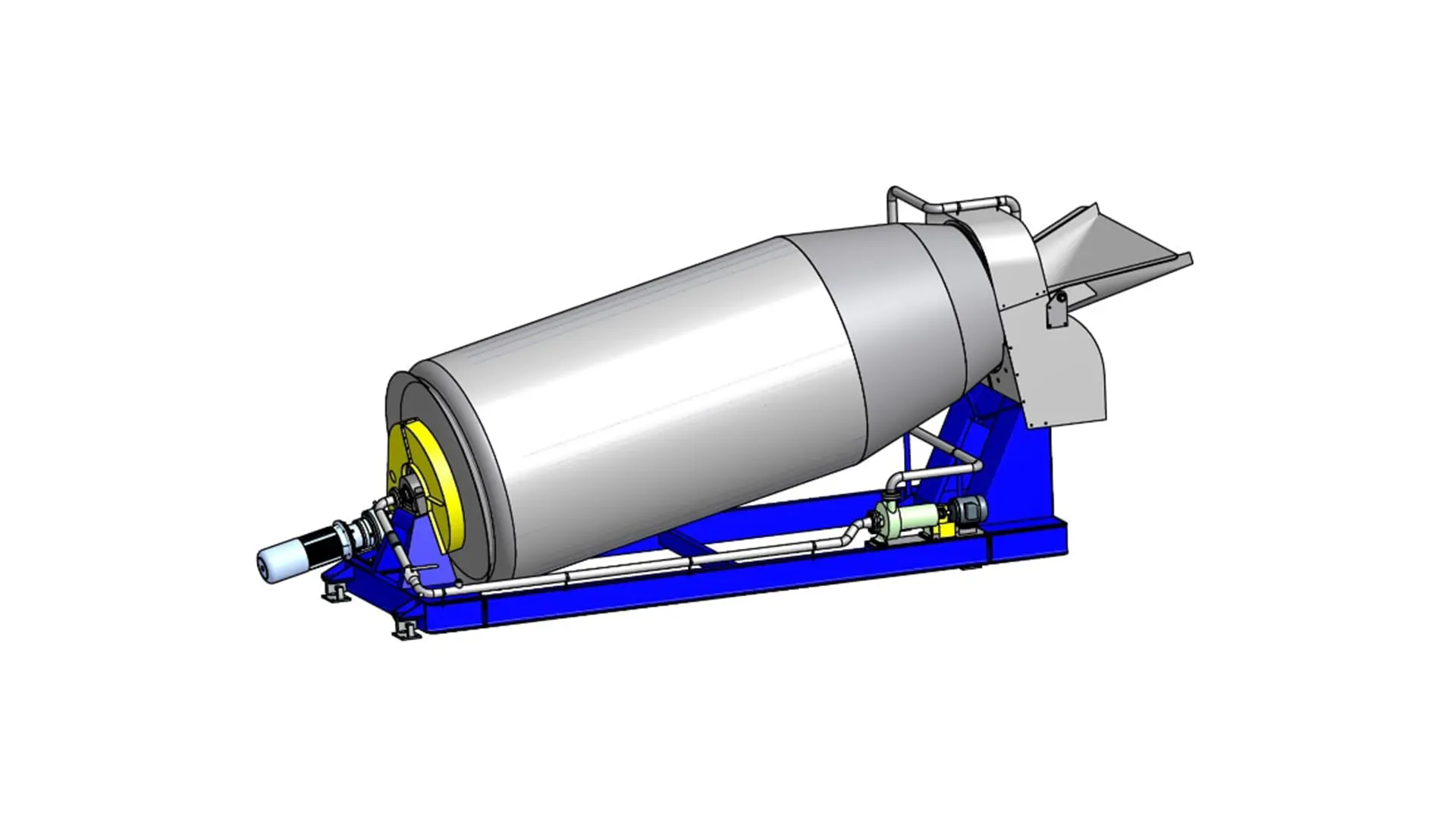

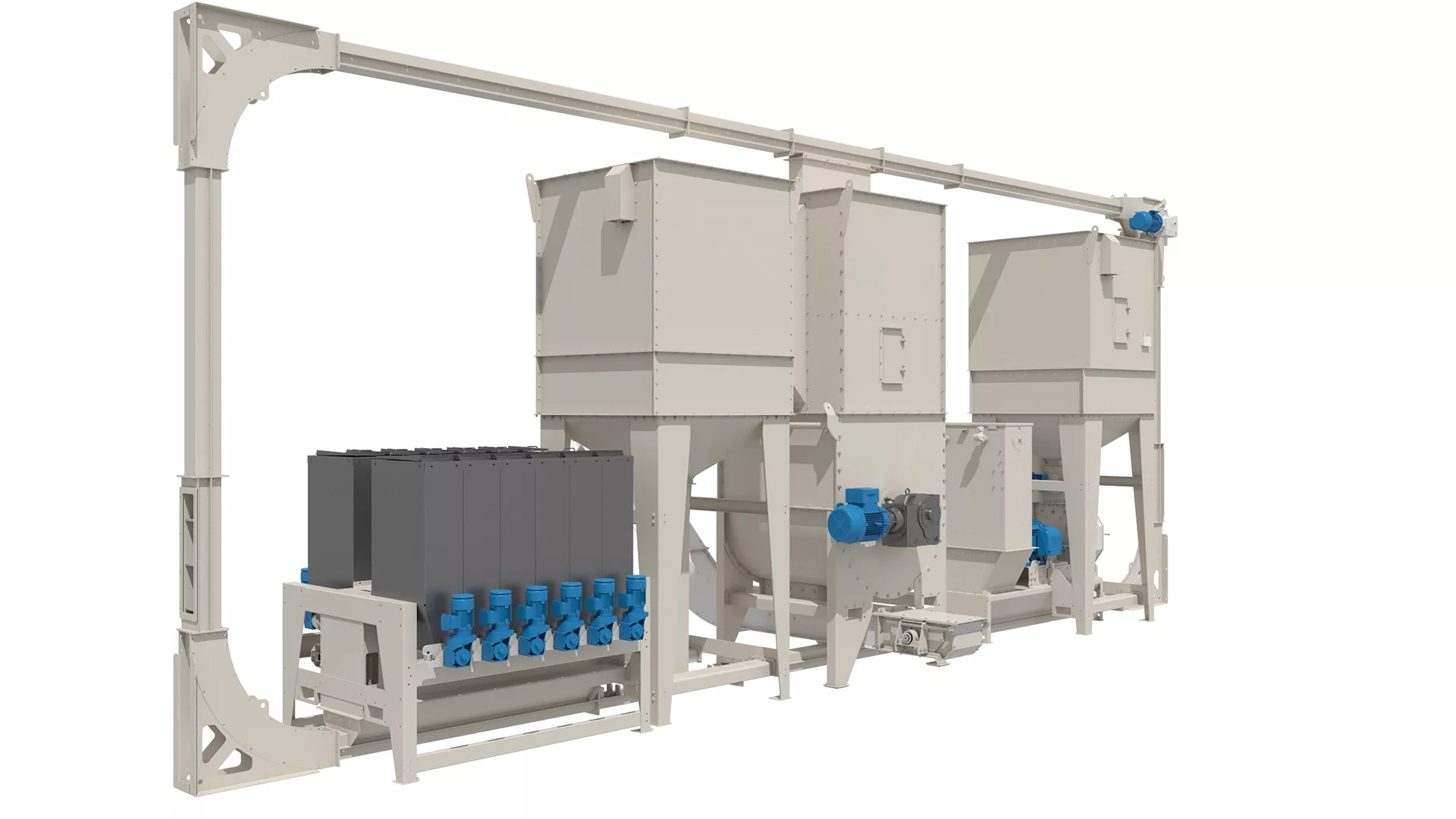

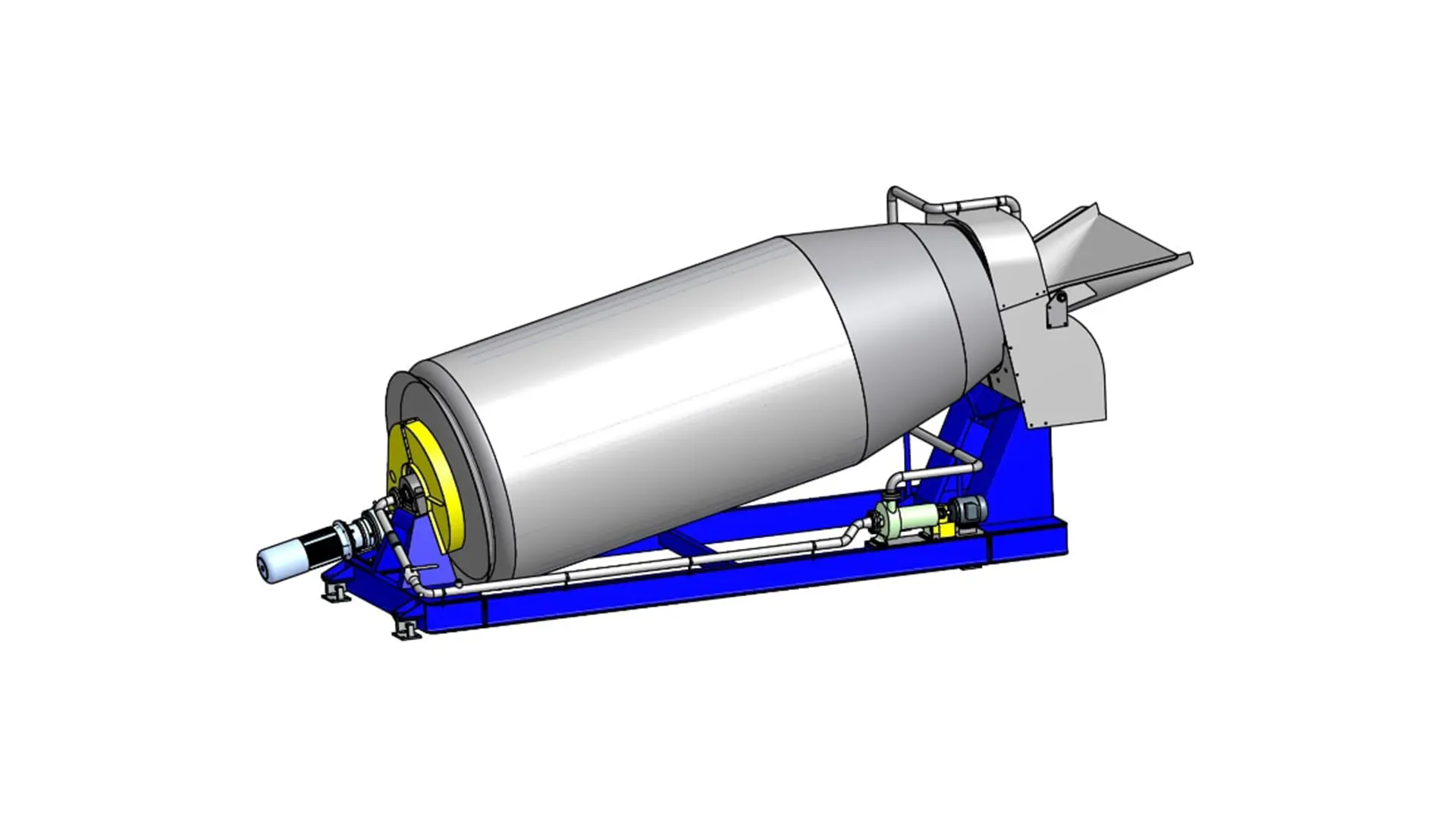

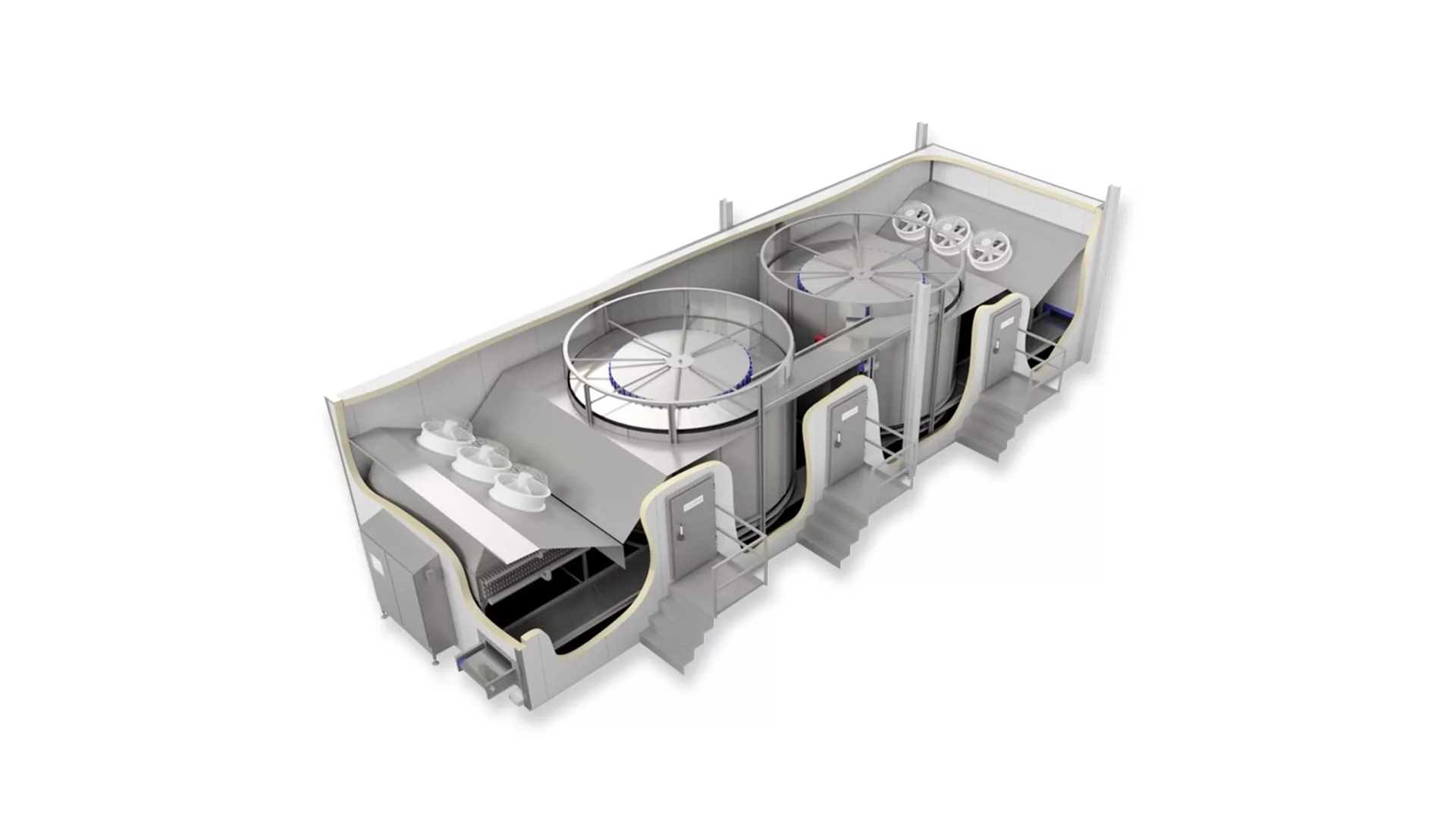

Milmeq, whose automated chilling and freezing systems have established the global benchmark for cooling and freezing meat, poultry and dairy products in cartons or crates, were acquired by MHM Automation in 2018.

Milmeq developed a global reputation for innovation when it introduced automatic chilling and freezing tunnels and plate freezers to the meat and dairy industries.

Since then, hundreds of installations have been completed worldwide for some of the biggest names in meat, poultry and dairy.

Milmeq systems are typically custom designed and installed on-site. We provide a turn-key service from design and manufacturing to installation, commissioning and ongoing maintenance and support.

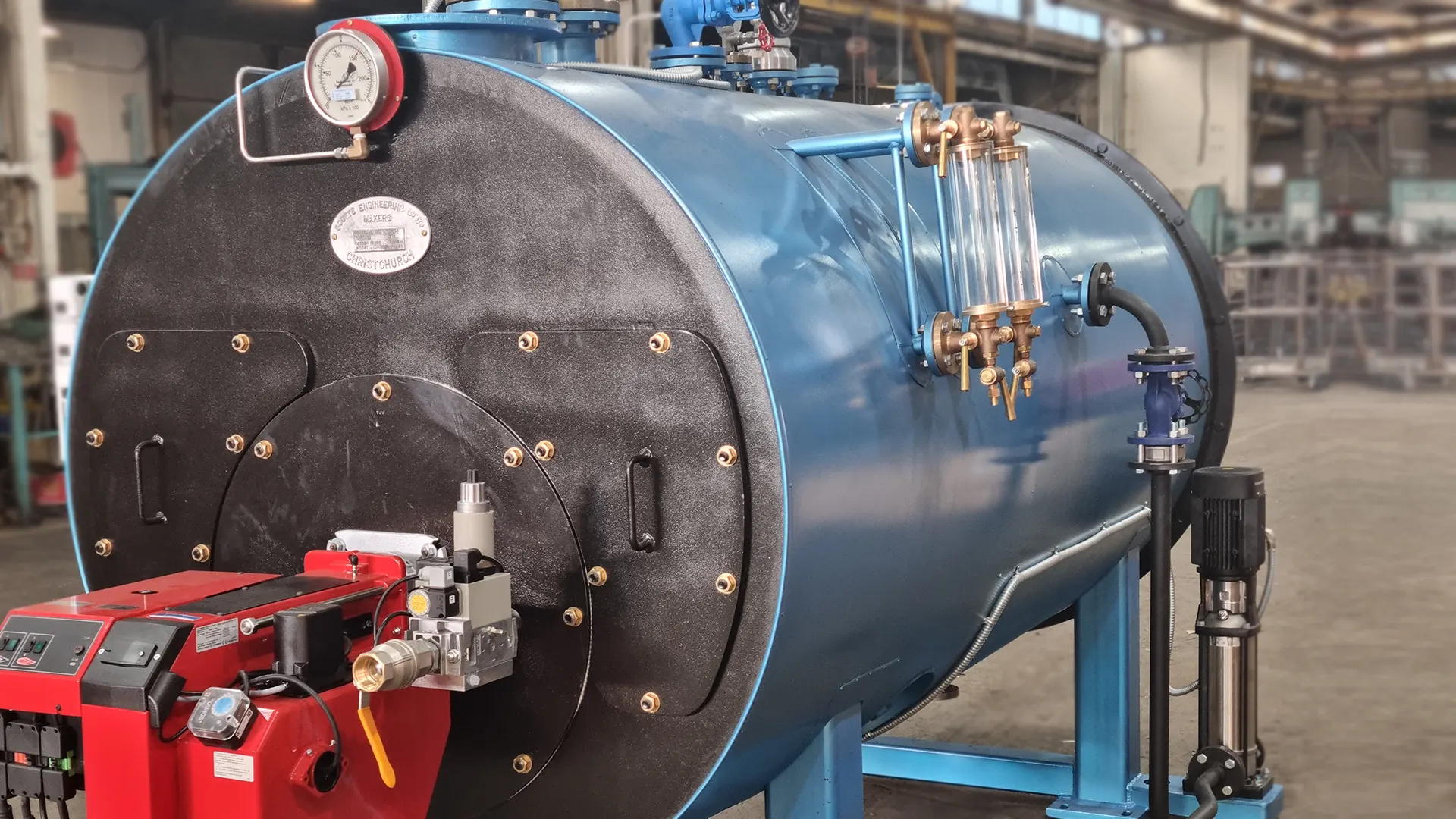

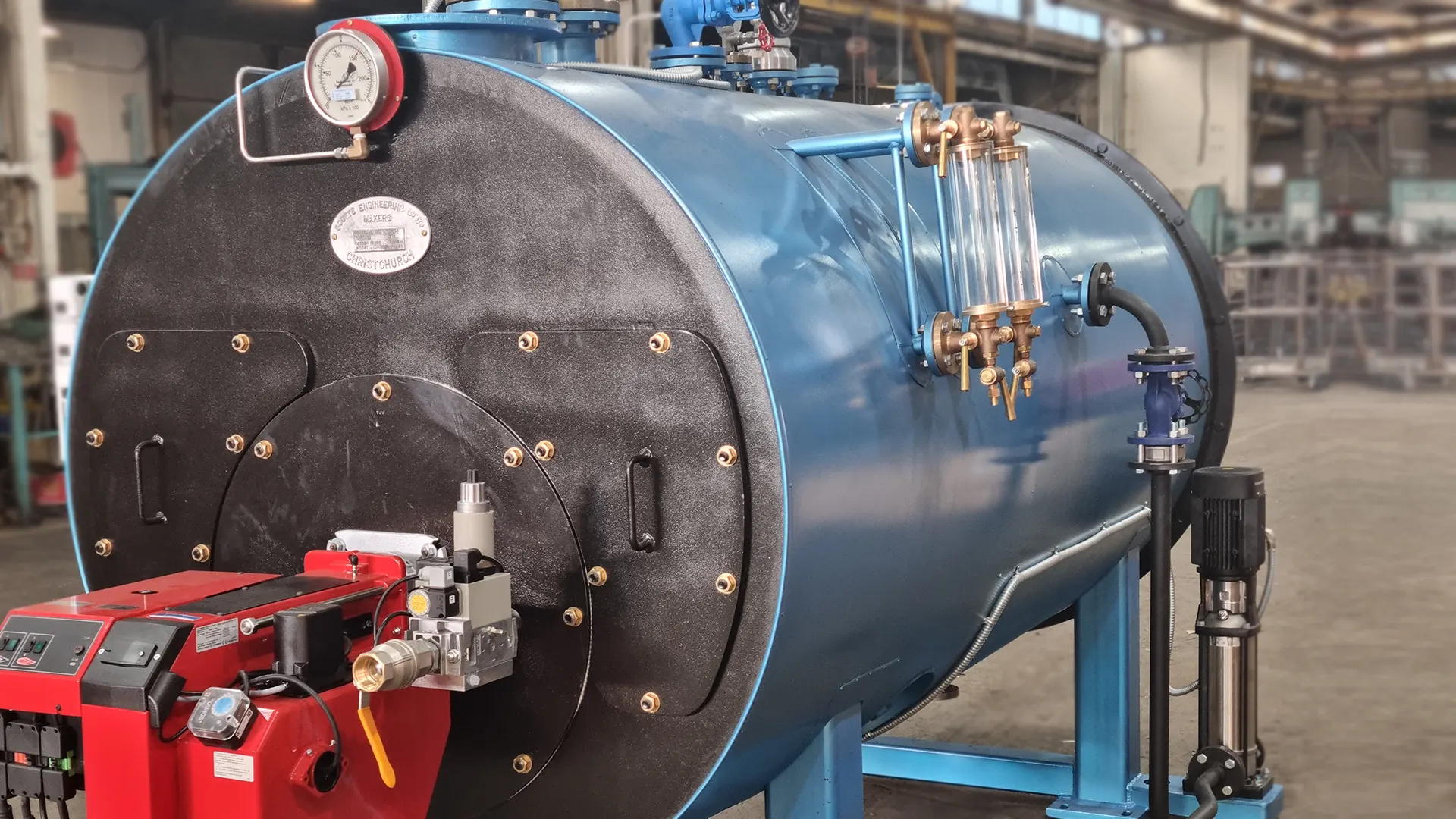

SCE (Southern Cross Engineering) is well-known for its expertise in designing, manufacturing, installing, and servicing equipment within the meat, dairy, grain, timber, and infrastructure sectors across New Zealand and Australia. In 2021, we completed the acquisition of SCE.

Our technology-led solutions include industry-leading grain stackers, pressure vessels and related boiler systems and timber processing equipment. We also provide heavy fabrication services and have expertise in solutions for agricultural applications and Antarctica.

Wyma post-harvest vegetable and fruit handling equipment is recognised as world leading and used by processors in more than 50 countries. We added Wyma to our portfolio through an acquisition in 2023.

The Wyma product range includes bulk product handling, washing, drying, peeling, cooling, inspection, packaging and more. Complete line solutions are available for processing carrots, onions, potatoes and fruit.

The S-Clave is an innovative sterilisation technology system for surgical devices and instruments.

The system sterilises surgical devices and equipment in a non-porus container that comes out of the autoclave sealed.

The product is revolutionary for the medical sterilisation market with the following key attributes:

We are currently working on the commercialisation of the S-Clave technology in partnership with Atherton, Australia’s leader in sterilisation equipment and infection control products for the hospital, medical and scientific industries.

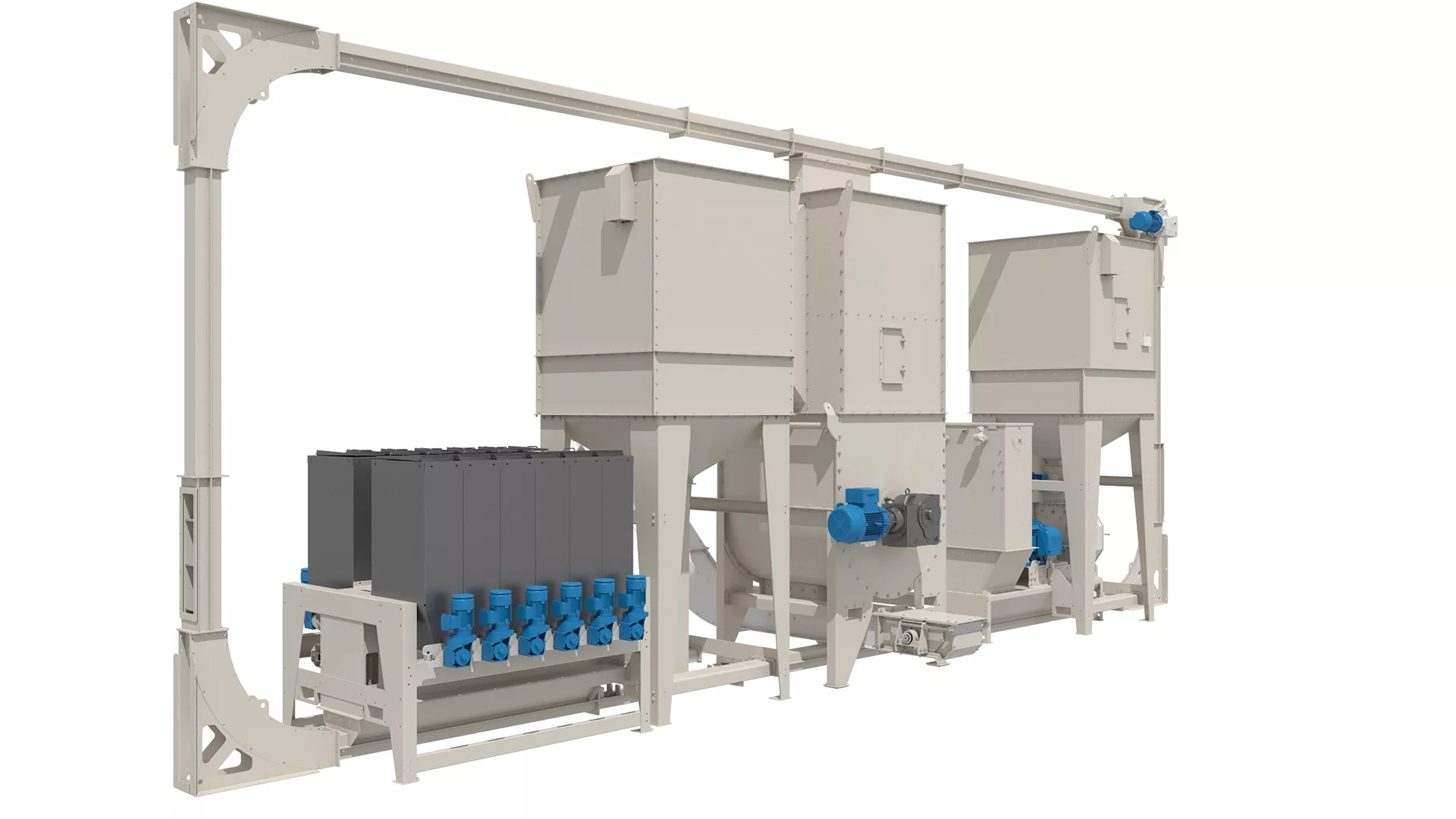

AGI is a global leader in systems and equipment the agriculture industry, including solutions seed, fertiliser, grain and feed handling for commercial and farm applications.

MHM Automation is the Australasian representative for AGI.

Australian-based Agridry is a specialised manufacturer of dryers for agricultural and food processing operations. It provides mobile and permanent solutions for drying grain and other commodities.

MHM Automation is the New Zealand representative for Agridry products.

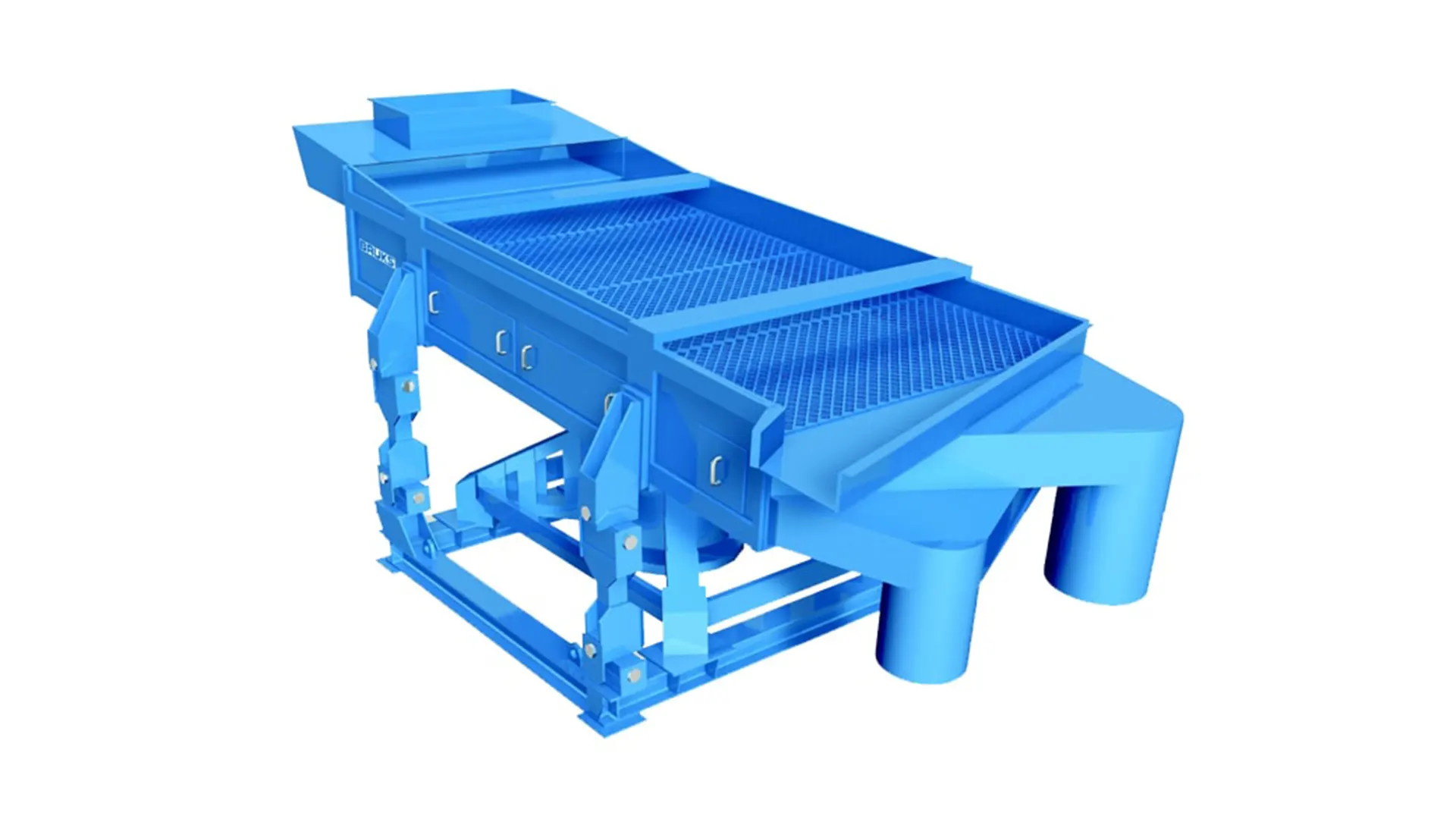

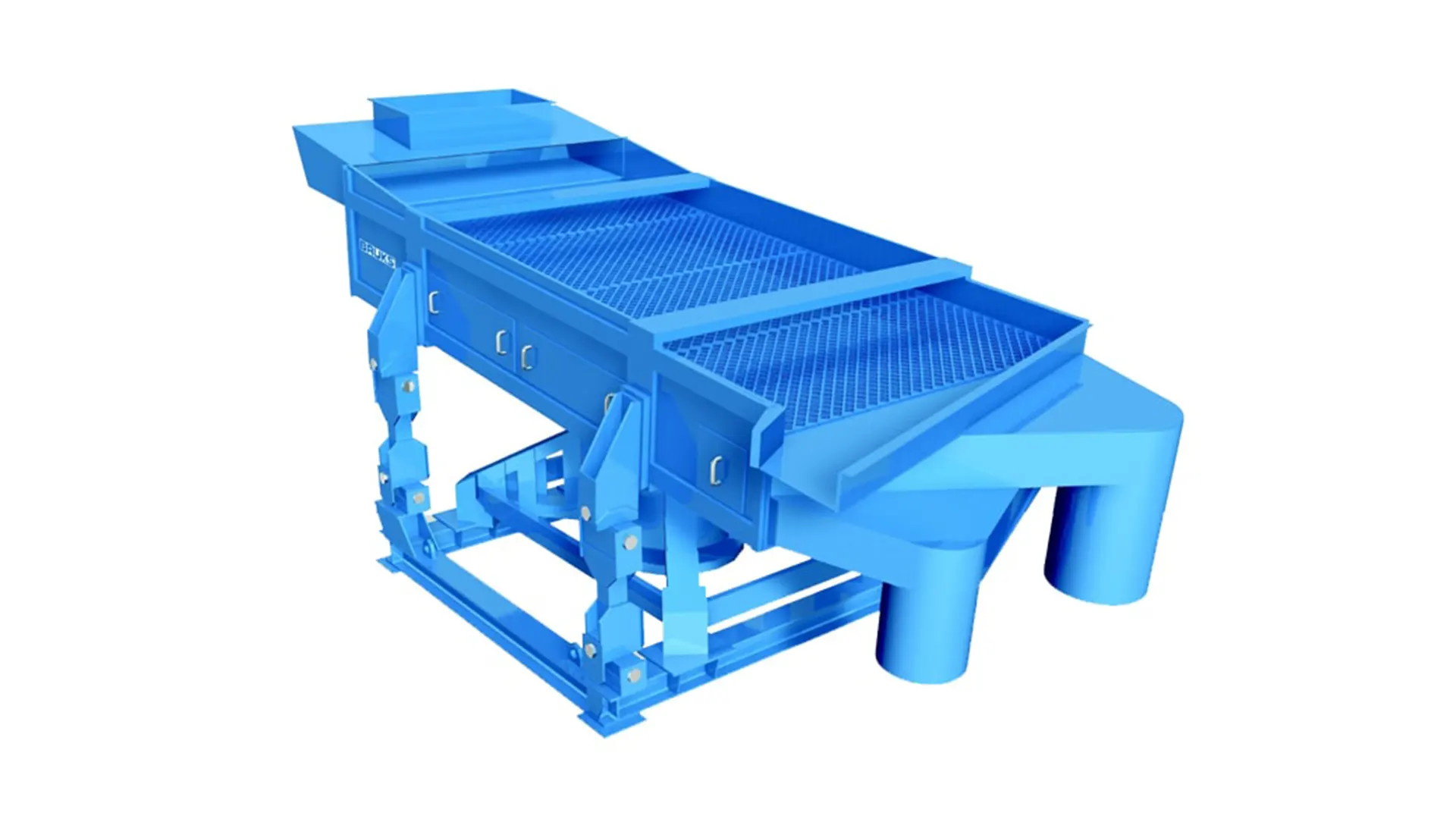

Bruks Siwertell is a global leader in wood handling and processing systems, based in Sweden.

MHM Automation represents Bruks stationary and mobile chipping systems in Australia.

Carsoe, from Denmark, is a world-leading manufacturer of stainless steel solutions for the seafood and food processing industries.

MHM Automation represents Carsoe vertical plate freezers in Australia and New Zealand.

Konecranes is a world leader in lifting equipment for manufacturing and process industries, shipyards, ports and terminals.

MHM Automation represents Konecranes products in New Zealand and Australia.

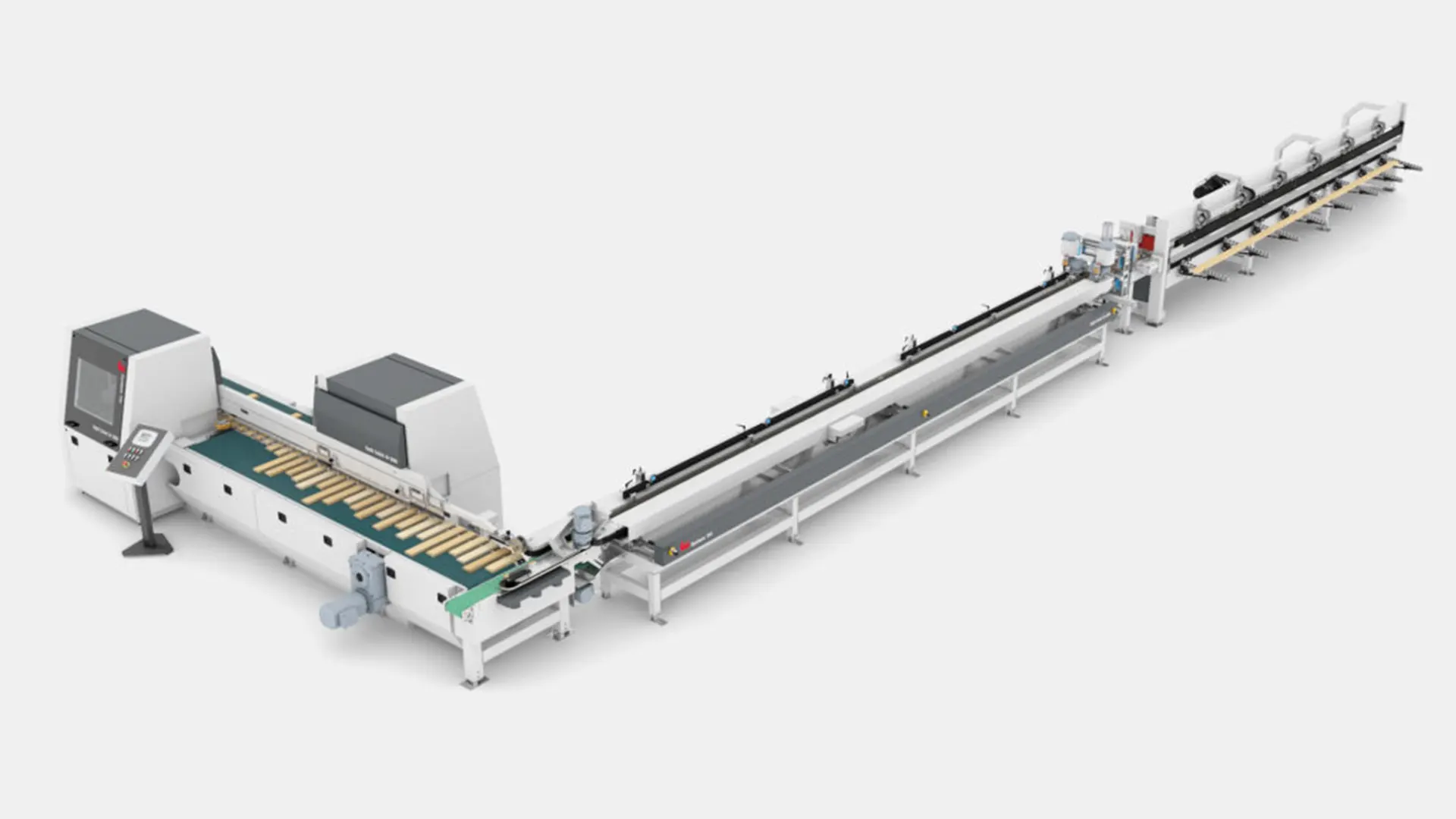

Leadermac is recognised as a world-class manufacturer of four-sided moulders for the timber industry.

MHM Automation represents Leadermac moulders in New Zealand and Australia.

Brazilian-based Omeco is recognised as a leader in the manufacture and supply of equipment for the plywood industry worldwide.

MHM Automation is the Australasian representative for Omeco plywood processing equipment.

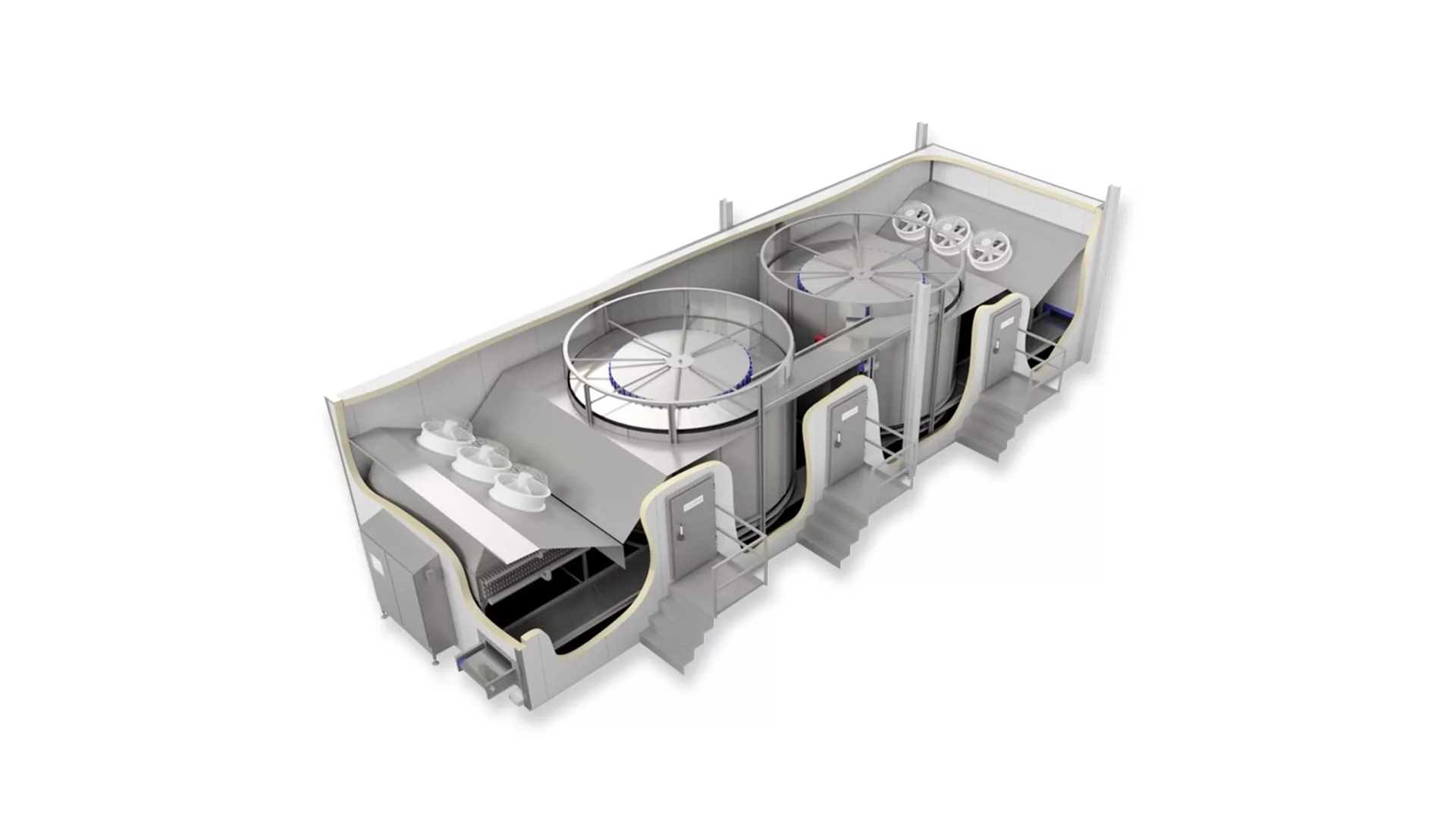

UK-based Starfrost provides industrial cooling solutions for the food industry, with particular expertise in spiral freezers and IQF.

MHM Automation represents Starfrost in New Zealand and Australia.

Stenner is internationally recognised as a leader in bandsaw technology. Stenner machinery is renowned for providing high performance over a long service life.

MHM Automation represents Stenner bandsaws in Australia and New Zealand.

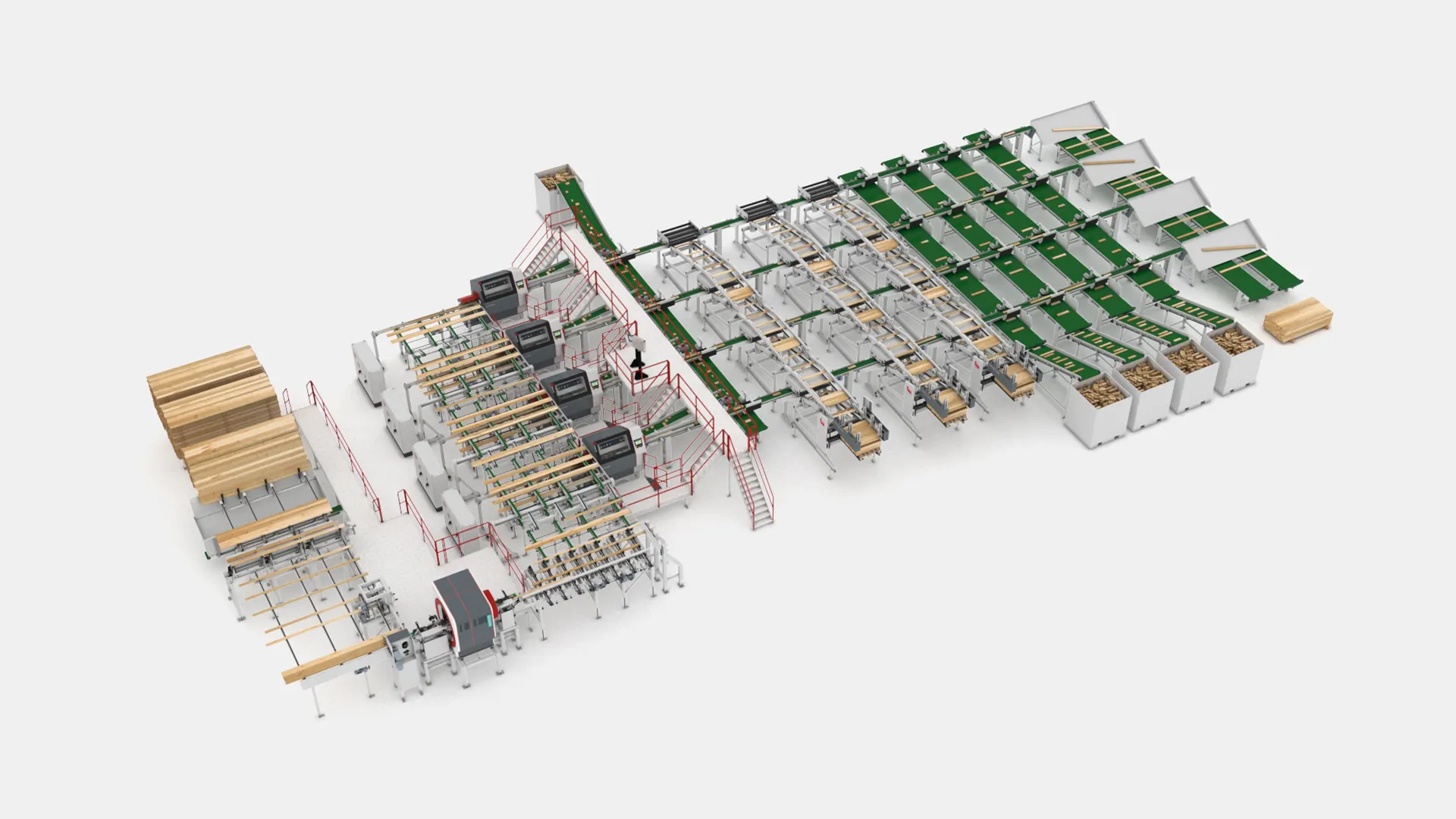

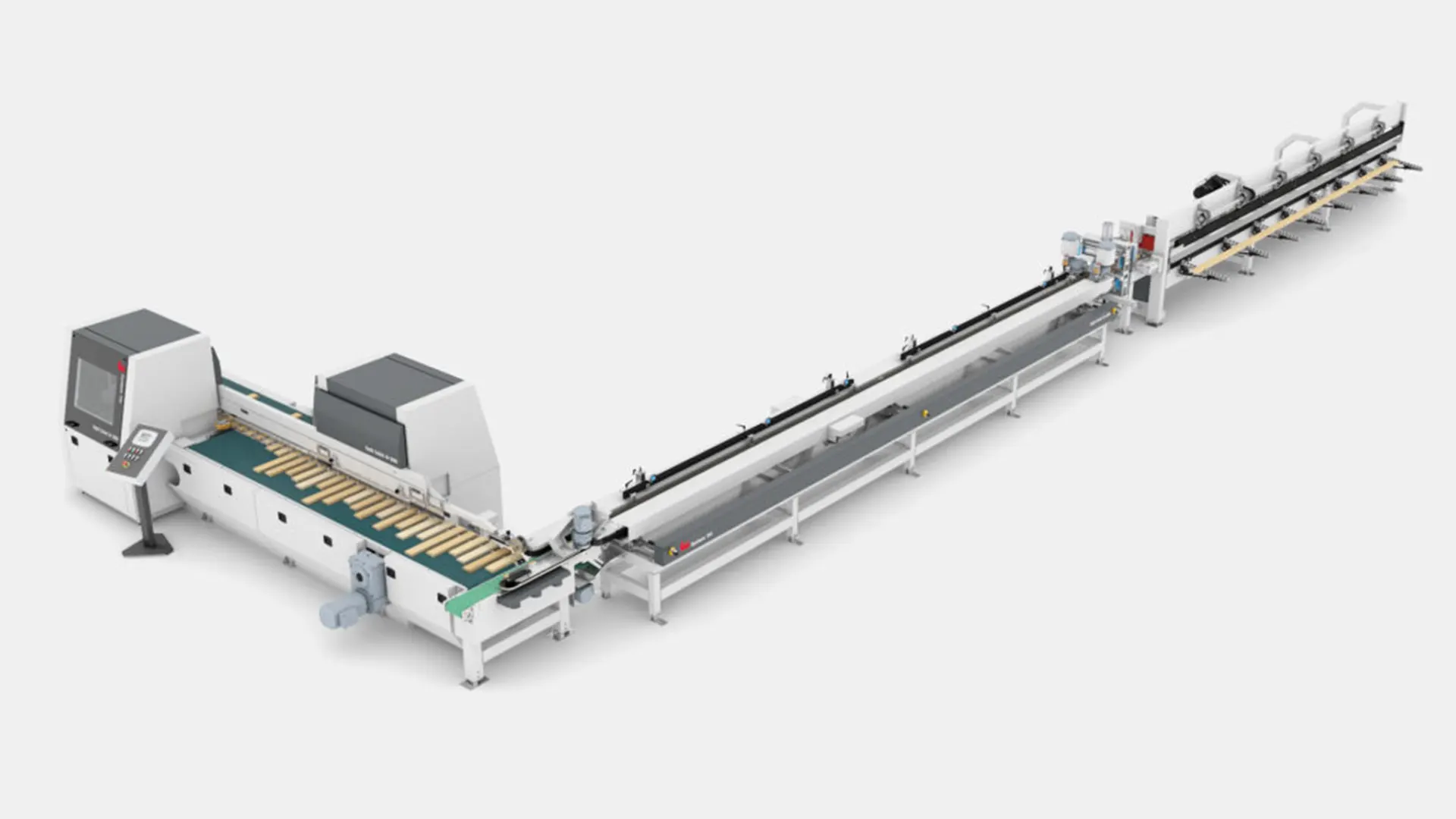

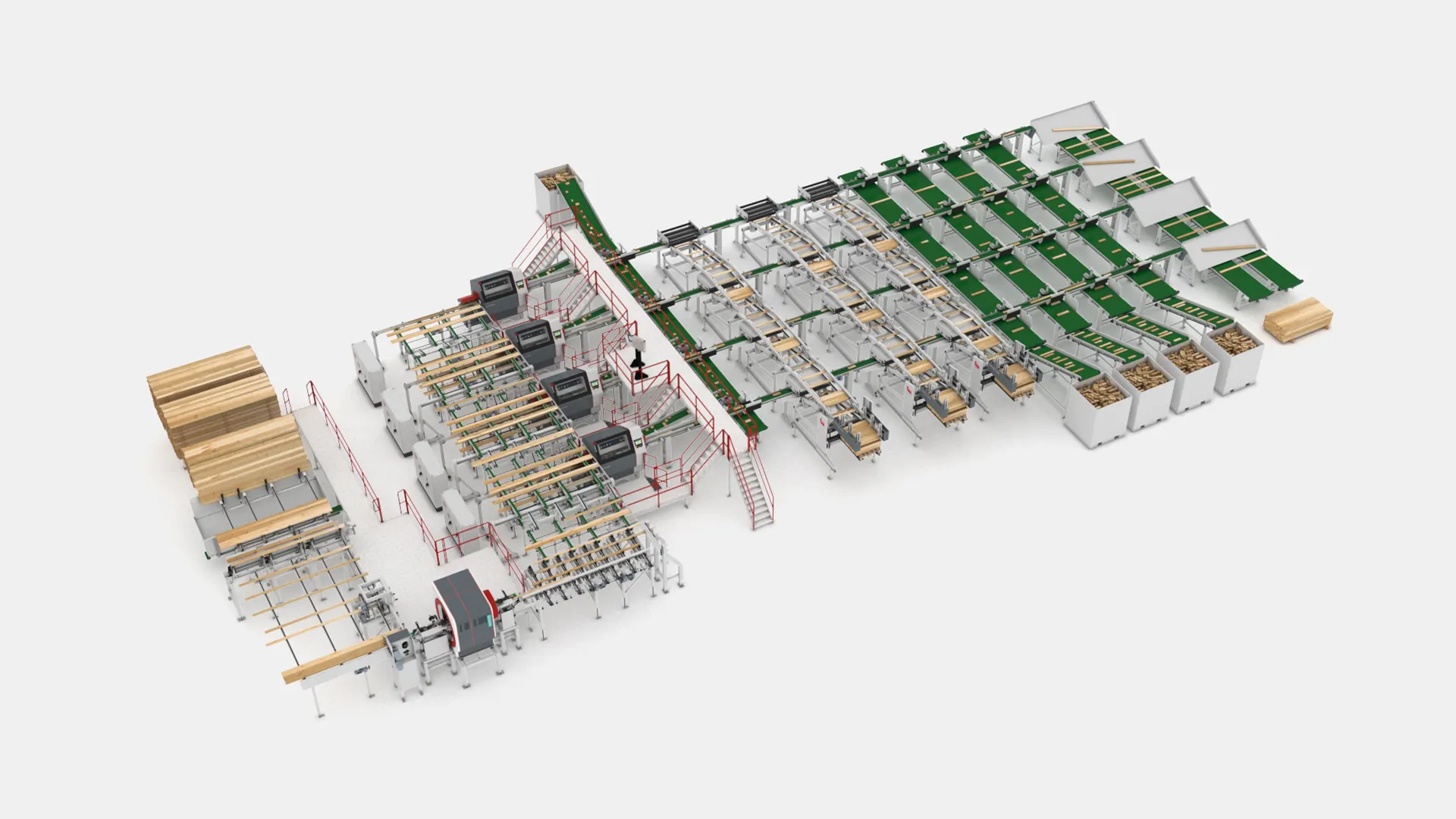

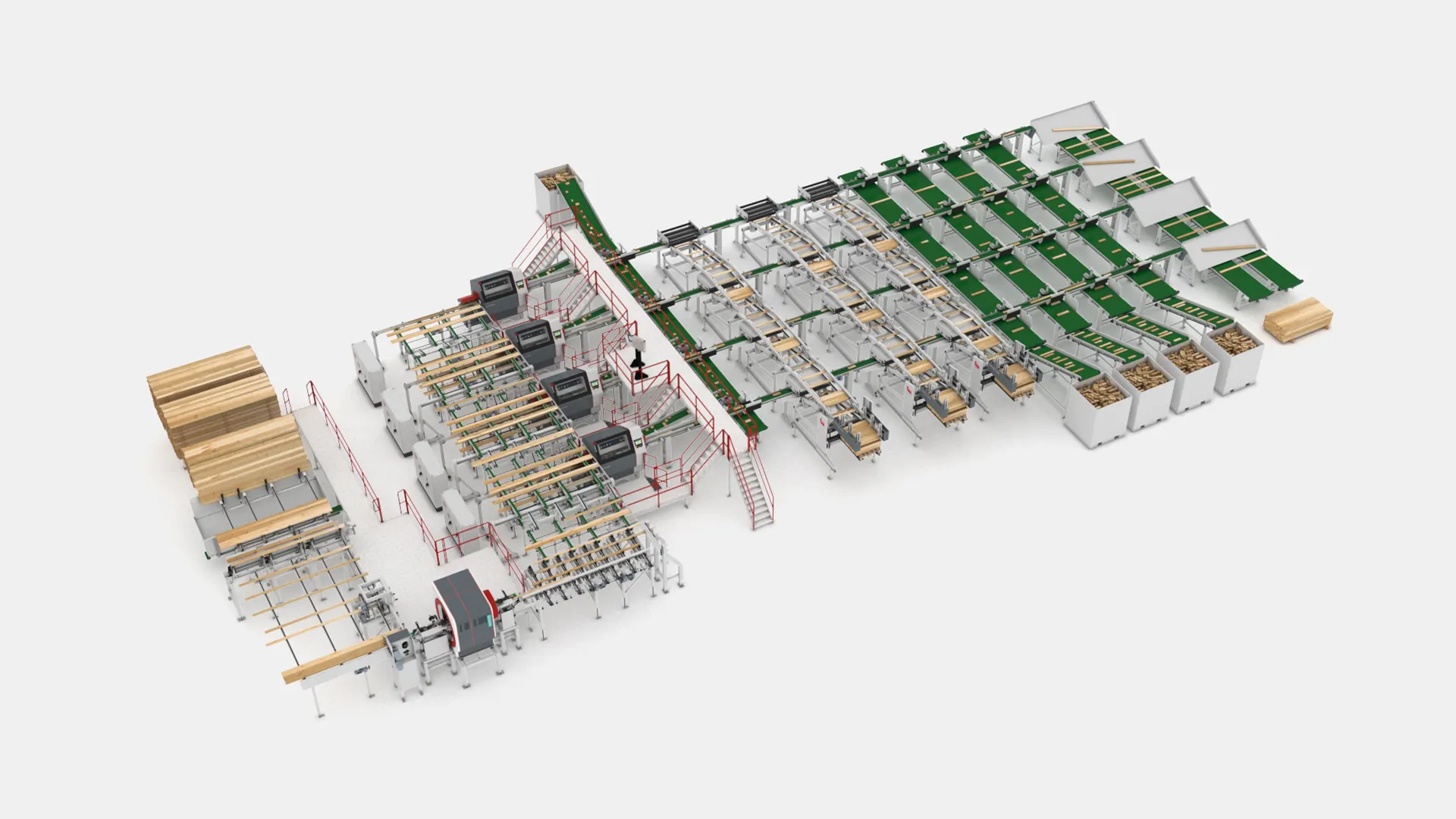

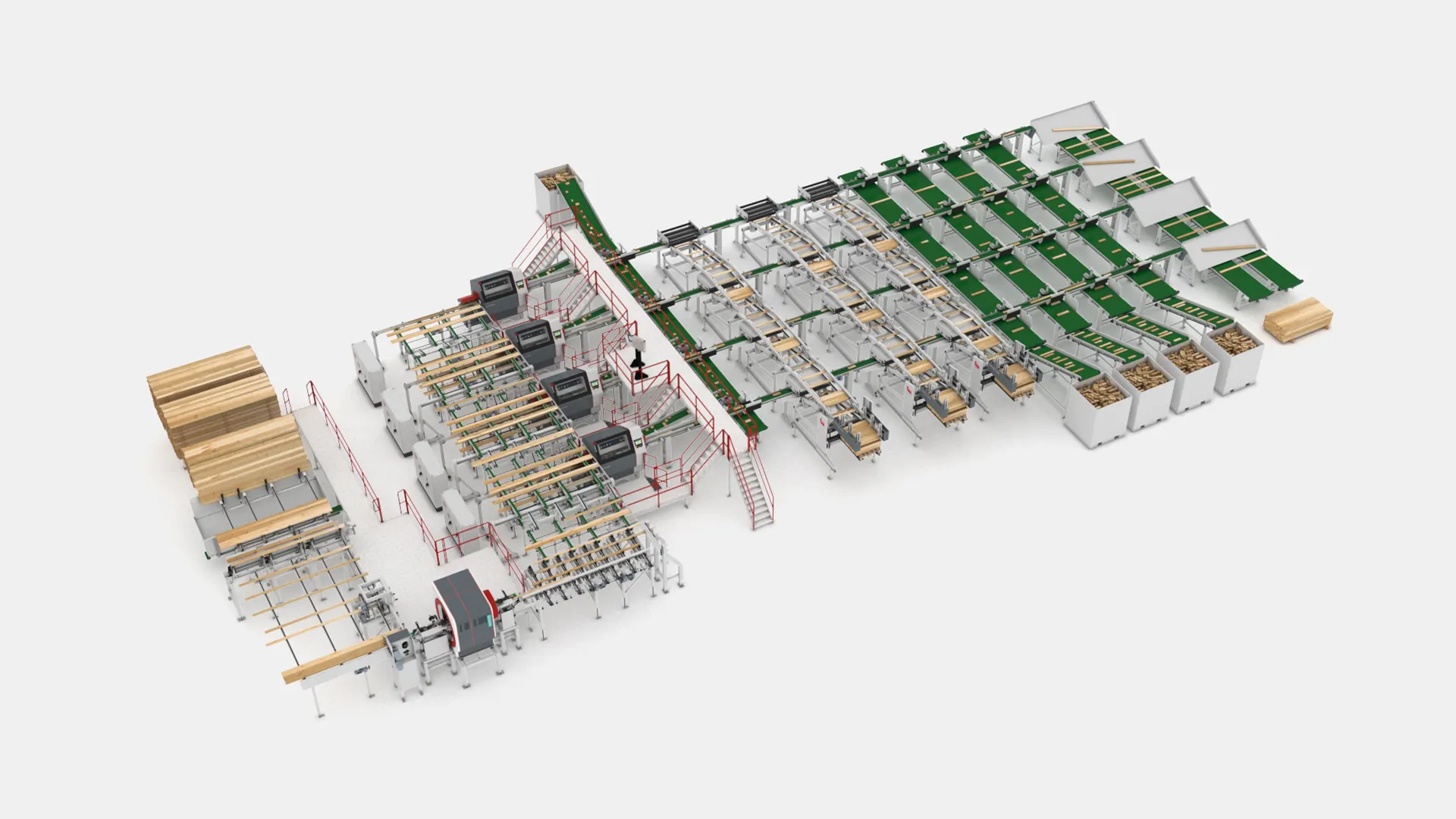

Part of the HOMAG Group, System TM is a leading global supplier of customised solutions to the timber processing industry.

MHM Automation is the Australian representative for their finger jointing and complete line solutions.

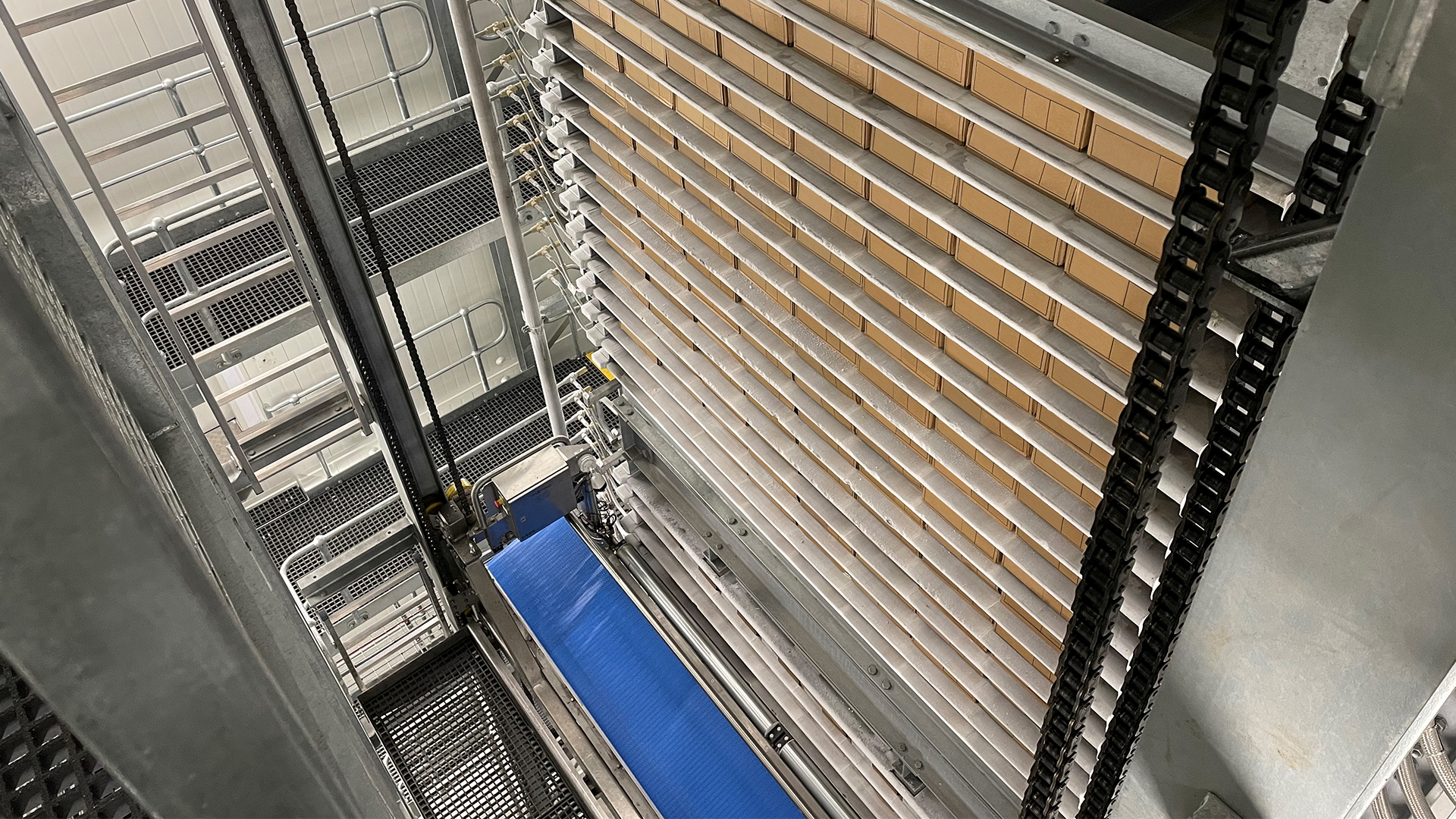

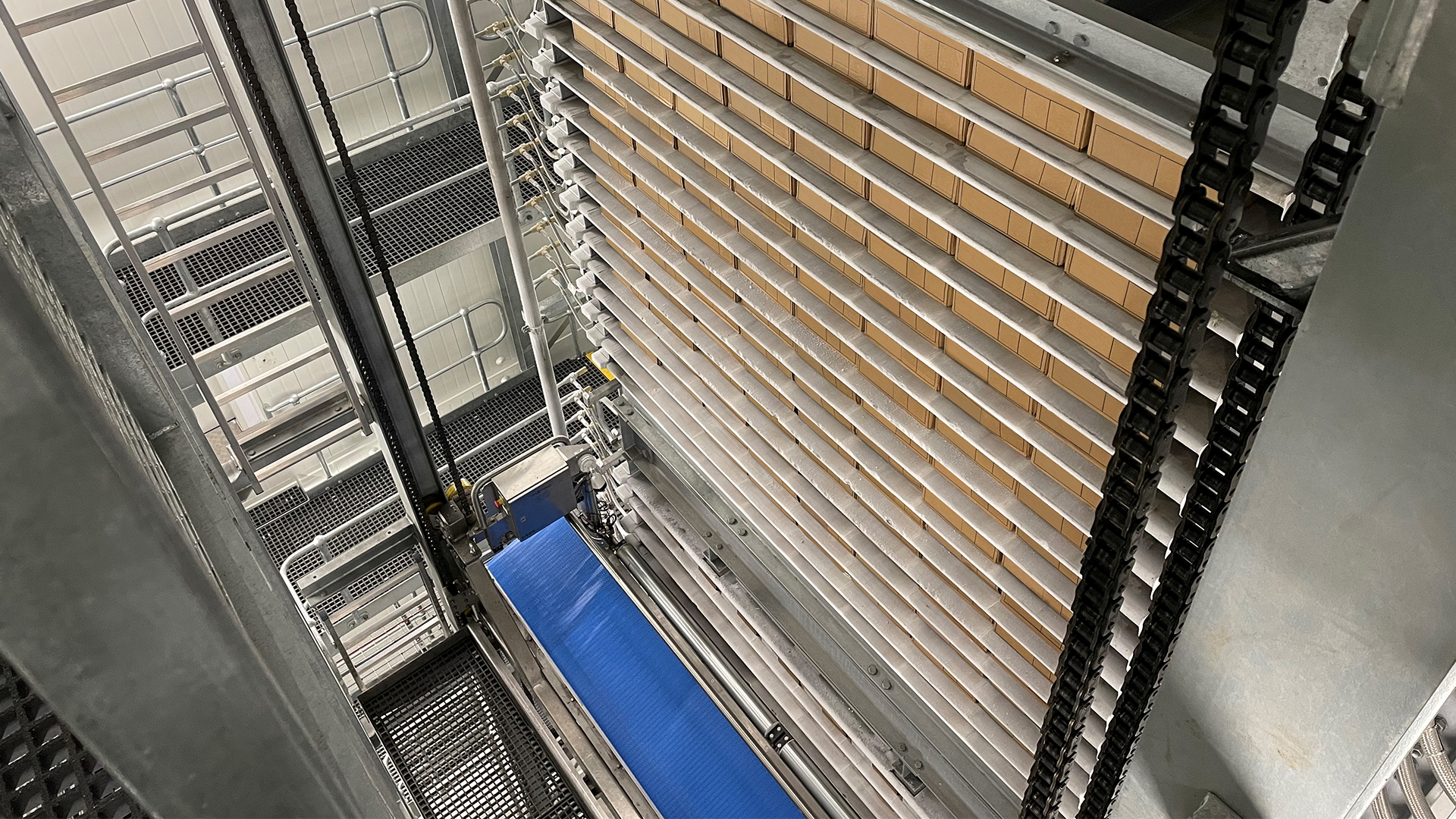

TGW is an intralogistics specialist with particular expertise in storage and retrieval systems (ASRS).

MHM Automation represents TGW automated storage shuttle systems in New Zealand and Australia.

Calhoun Super Structure fabric buildings is a family-owned business based in Canada. With over 30 years’ experience, they design, engineer, and manufacture leading edge fabric structures.

MHM Automation represents Calhoun in New Zealand and Australia.

Automates the removal of cartons from pallets stacked in random patterns and with multiple carton sizes.

Custom-designed and fabricated storage tanks for suitable for chemicals and acids.

Stainless steel fabrication of sculptures and architectural features for domestic and commercial projects.

High performance ASRS shuttle and elevator system. Suitable for chilled and frozen products.

Safely automate pallet and crate movements, even in a congested working environment.

Prepares bagged cheese blocks for vacuum sealing.

In-line leak detection system for vacuum packed cheese blocks and other products.

Re-orientate products before or after vacuum packing and save space on the production line.

Industry-leading vacuum packaging system for cheese and other products.

Custom designed and fabricated multi-fuel boilers and heat plants.

A complete range of drum and disc wood chippers for low and high throughput operations.

Site-constructed silos, suitable for biogas, waste water treatment plants and aluminium smelters.

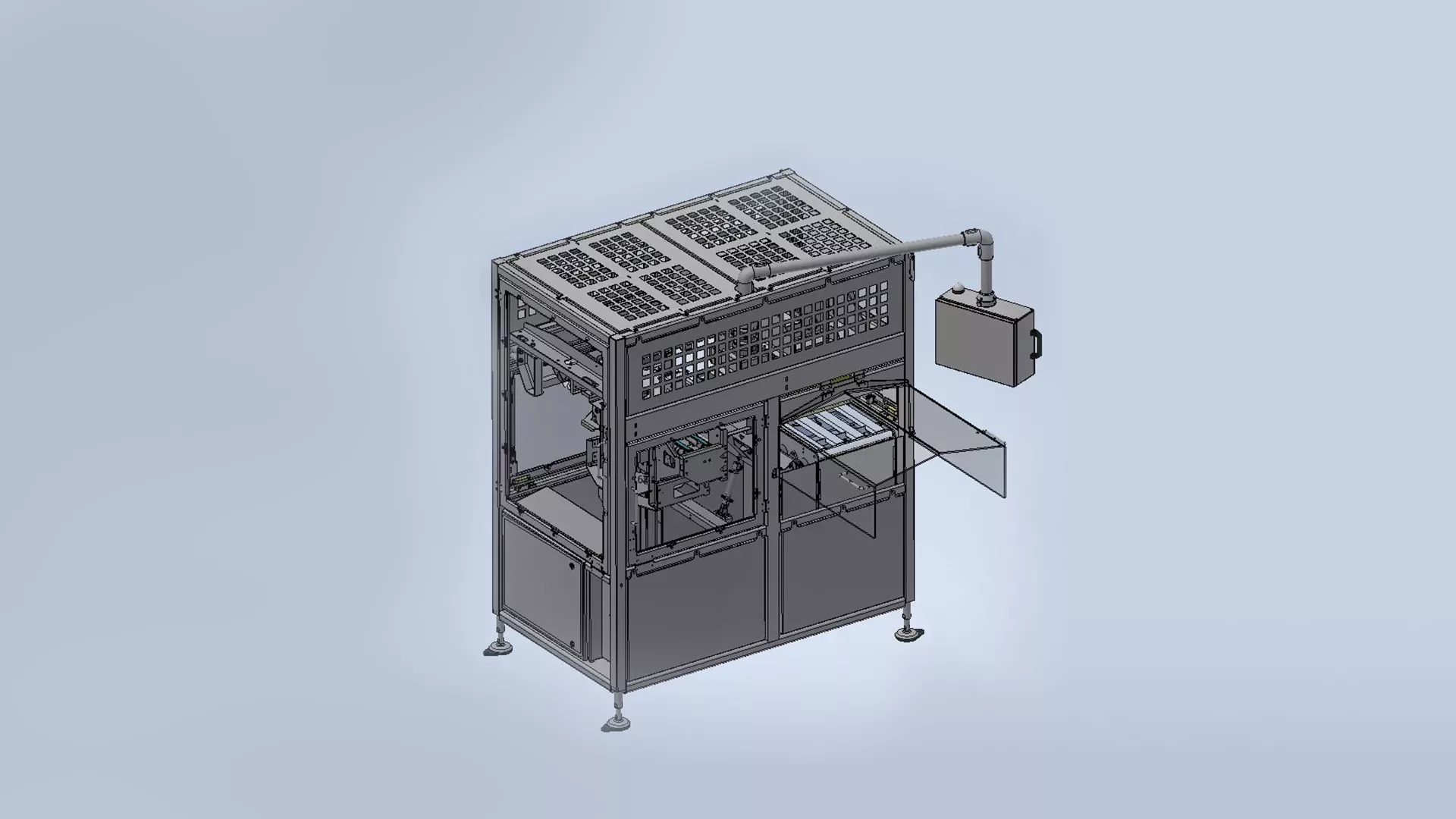

Automatically erect cartons at speeds of 10-25+ cartons per minute. Solutions for chilled and frozen product.

Automatically place and seal lids on cartons. Compact machine designed for chilled and frozen products.

A variation of the SRT for cheese processors, providing fast chilling to preserve product quality.

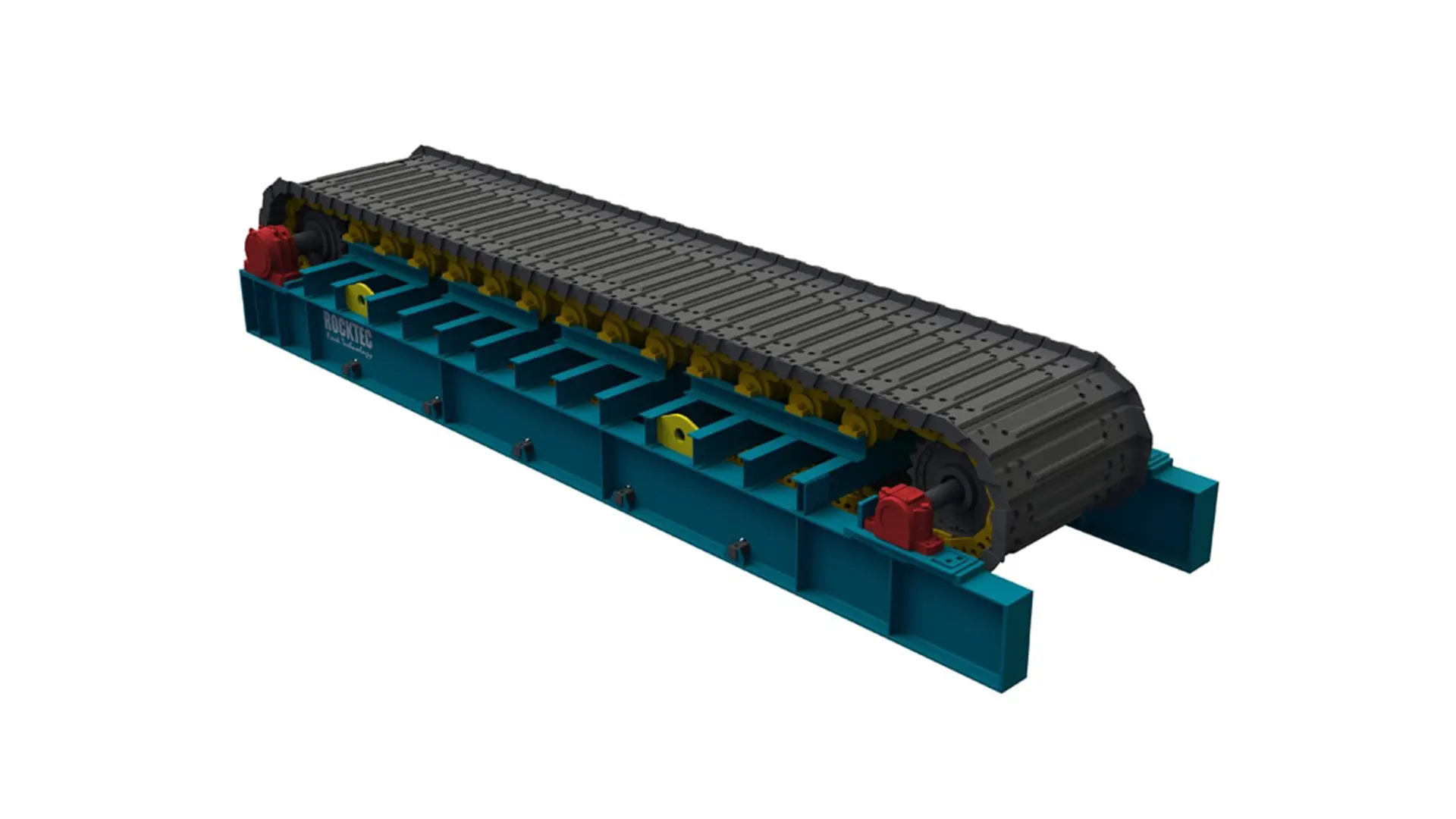

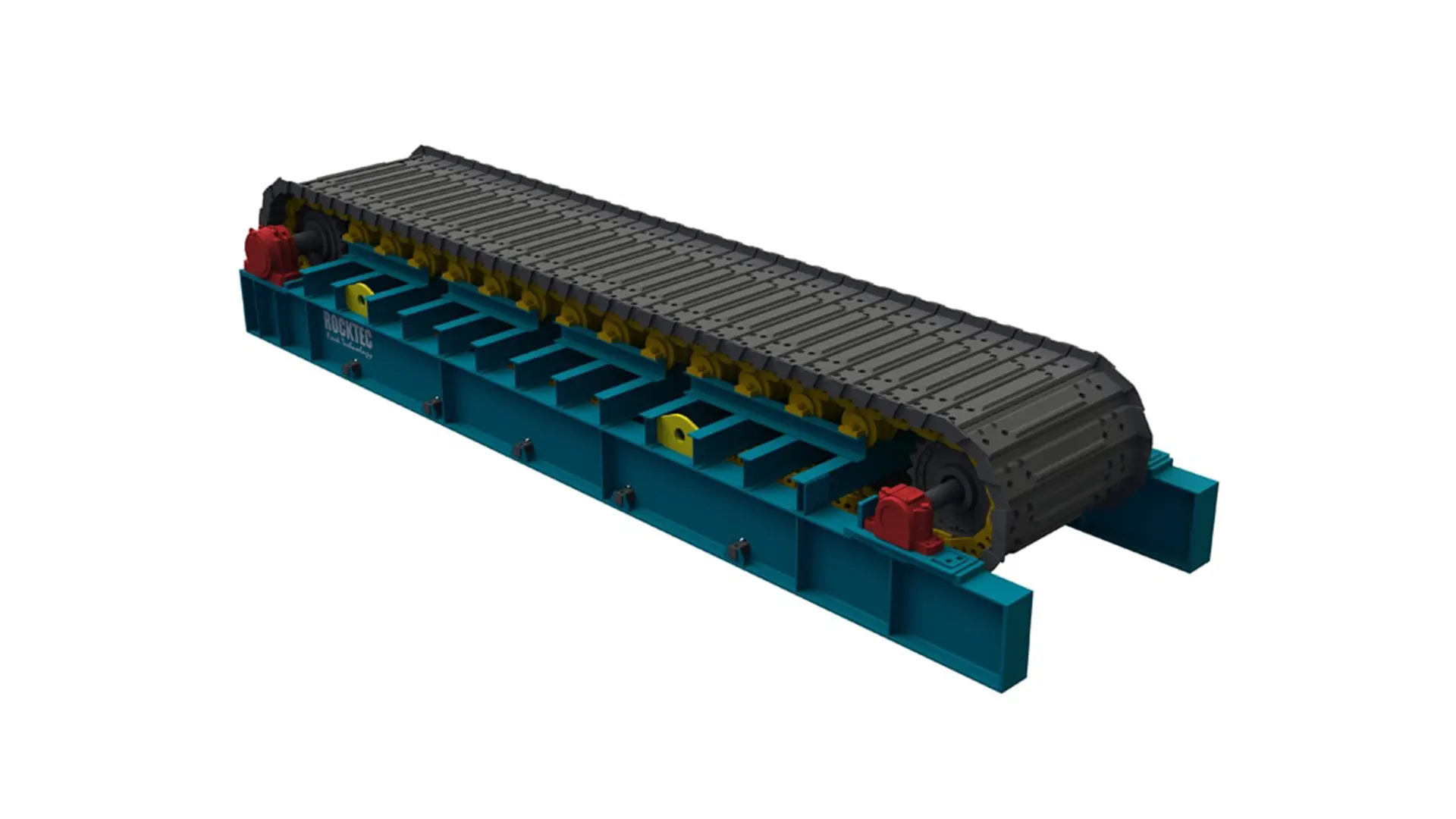

Custom designed conveyor systems for all applications, including in-plant, long distance overland and stockpiling conveyors.

Kettles, pressure cookers, cooking pans, mixing, pasteurising and cooling vessels.

De-palletise, de-box and re-palletise 40lb / 20kg cheese blocks the efficient way.

A complete range of debarking systems, including head, ring and drum debarkers.

Inspects naked cheese blocks for mould and foreign material prior to further processing.

Custom-fabricated dished ends and heads for pressure vessels, tanks and other applications.

A versatile and cost-effective solution for grain storage.

Fast, energy efficient freezing of product in cartons or boxes. 24-hour cycle for 27kg meat cartons.

Affordable and reliable palletising and de-palletising solution, ideal for medium throughput operations.

Achieve high capacity while maintaining gentle handling and minimal maintenance.

Processing solutions for agricultural raw materials.

Standard elevator sizes and capacities as well as customer designs for special applications.

Suitable for a wide range of processing applications, from small to large scale, ensuring minimal degradation.

Drying systems for grain, wheat and other free-flowing products. A full range of mobile and fixed solutions.

Milling equipment for rice milling, pulses processing, maize milling and seeds processing.

Standard mixers and customisable blending systems to suit your commercial or farm applications.

Storage systems that protect valuable grain. Solutions for on-farm and large-scale commercial use.

Industry-leading mobile grain stacker with drive over grid for handling bulk grain and wheat.

Complete solutions to machinery guarding to meet the latest safety standards.

Complete processing for all animal hide products.

Opens boxes of varying shapes and sizes at high speed, for non-sanitary operations.

World-leading crane technology for a broad range of industrial lifting applications.

Handling and processing equipment for large and small diameter logs.

Automatically compact meat in corrugated cartons, to deliver flat boxes for efficient container loading.

Automates the removal of vacuum bags from 20kg / 40lb blocks of cheese.

Removes cardboard cartons from 20kg / 40lb blocks of cheese at a rate of 16 blocks per minute.

Cobots work safely alongside people to automate repetitive tasks.

Custom fabrication of stainless steel benches and features for commercial and domestic applications.

Highly accurate weighing system for dosing micro feed ingredients with precision.

Custom design and fabrication for projects large and small. Specialists in hydro gates and bridge strengthening.

Four-sided timber moulders, from standalone machines to complete auto-planning moulder line solutions.

Automatic carton tunnel that accommodates various product types with different chilling or freezing times.

A full range of equipment for plywood processing.

Custom-manufactured hoppers and storage bins for powders and free-flowing solids.

A patented system for road and rail tankers, providing protection during filling, emptying and transportation.

Stainless steel tanks and tankers for transportation of liquids by road and rail. Insulated or non-insulated.

Automates the removal of vacuum bags from multiple cheese block types and sizes.

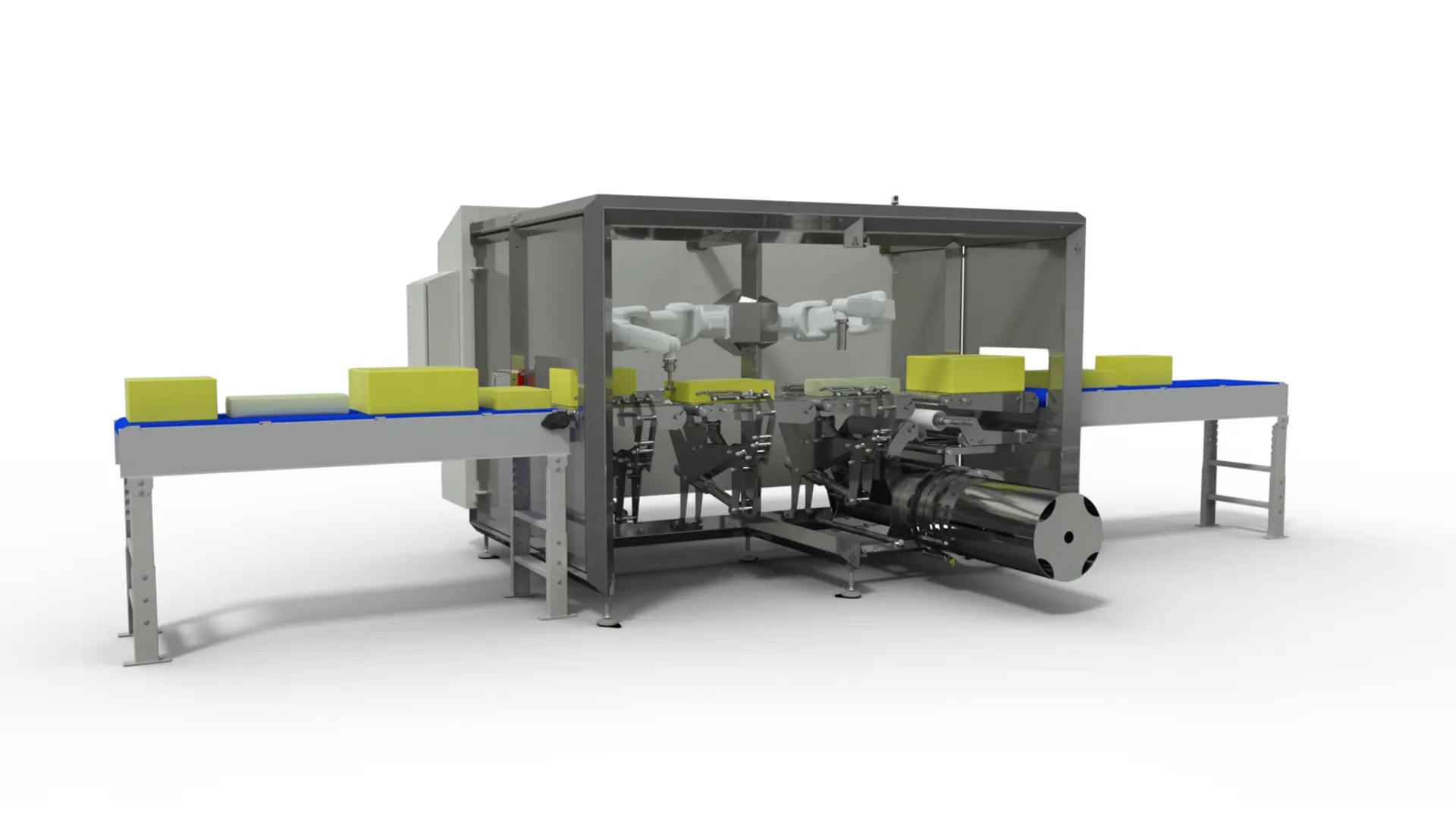

De-palletise, de-box, re-palletise and process multiple blocks the efficient way with the Robotic De-Boxing Cell.

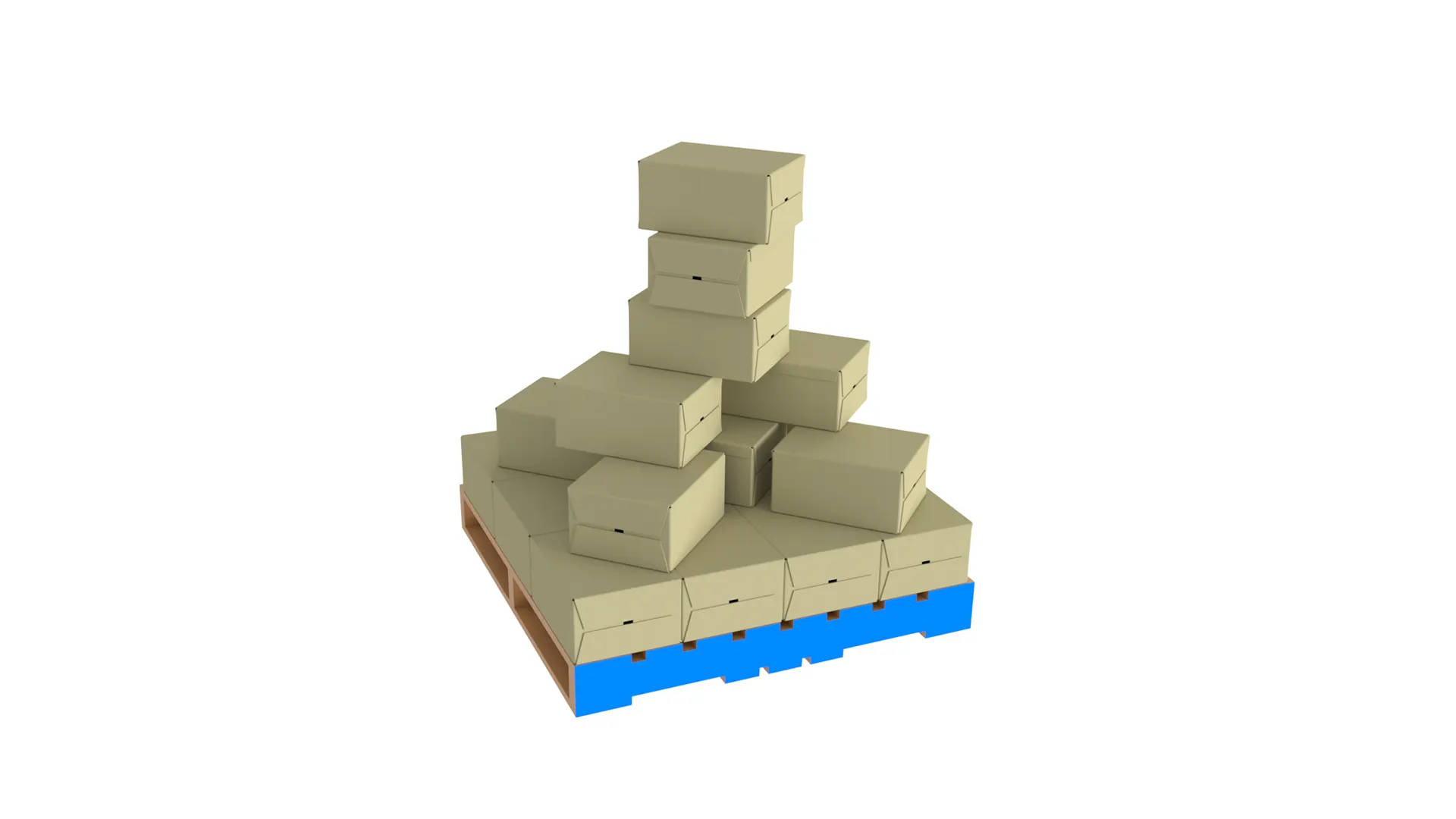

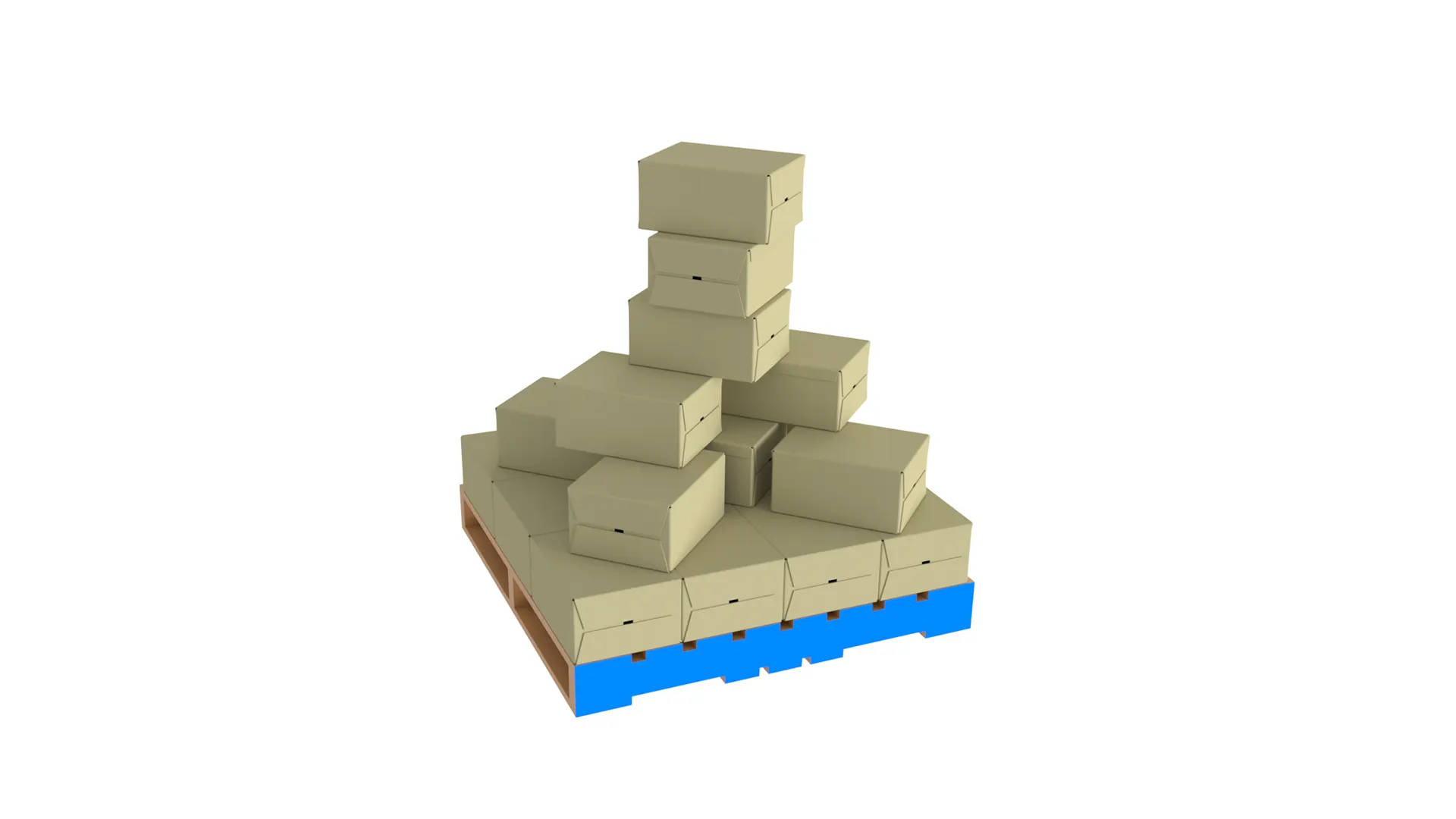

Efficient and reliable stacking of boxes onto pallets in high throughput operations.

Screen cleaners and waste conveyors for the intake screens of hydro power stations.

Screens to suit a variety of wood chip screening applications.

Compact palletising and de-palletising system for smaller operations.

Spare parts and after-sales service are available for all products supplied by MHM Automation.

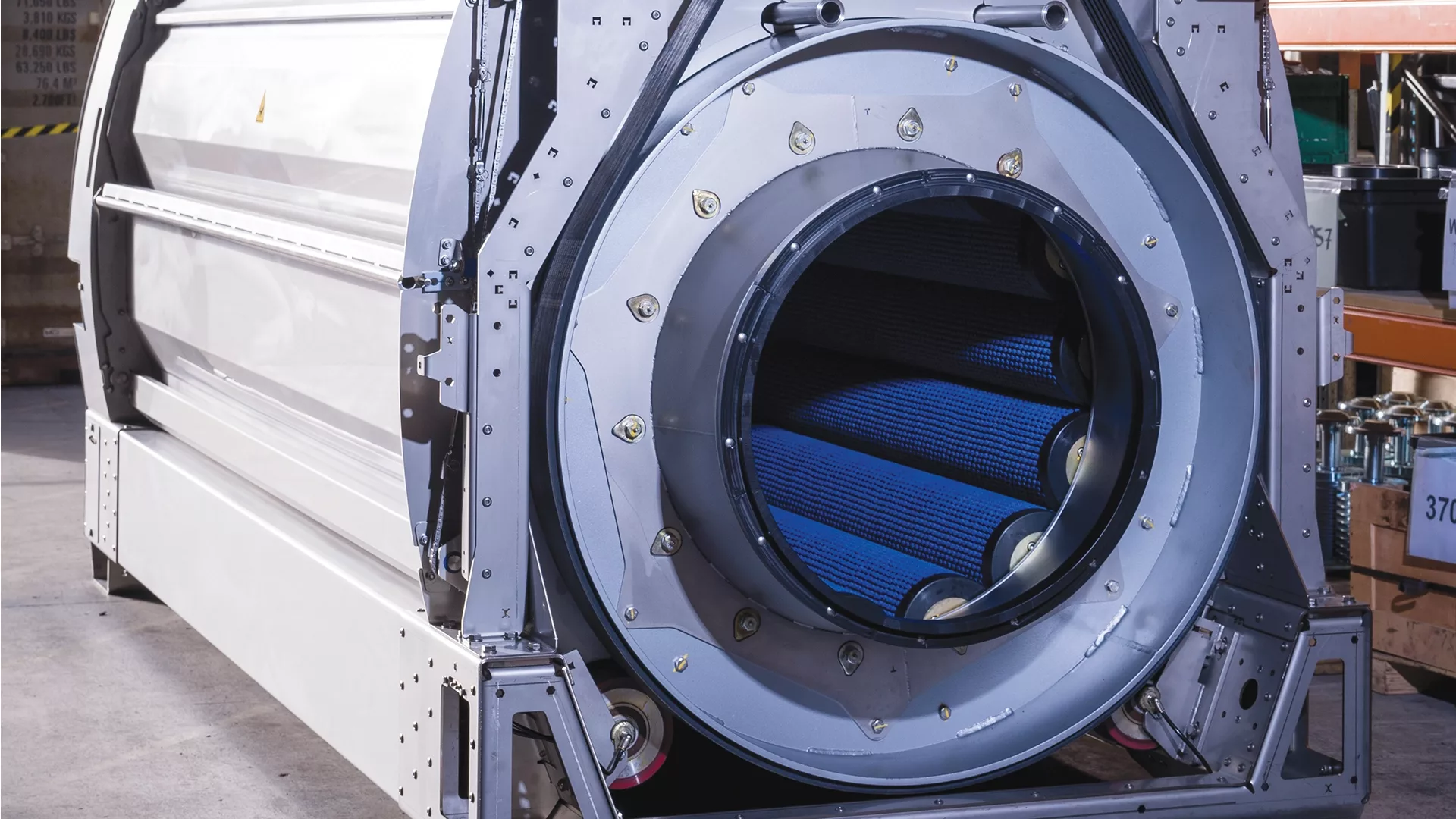

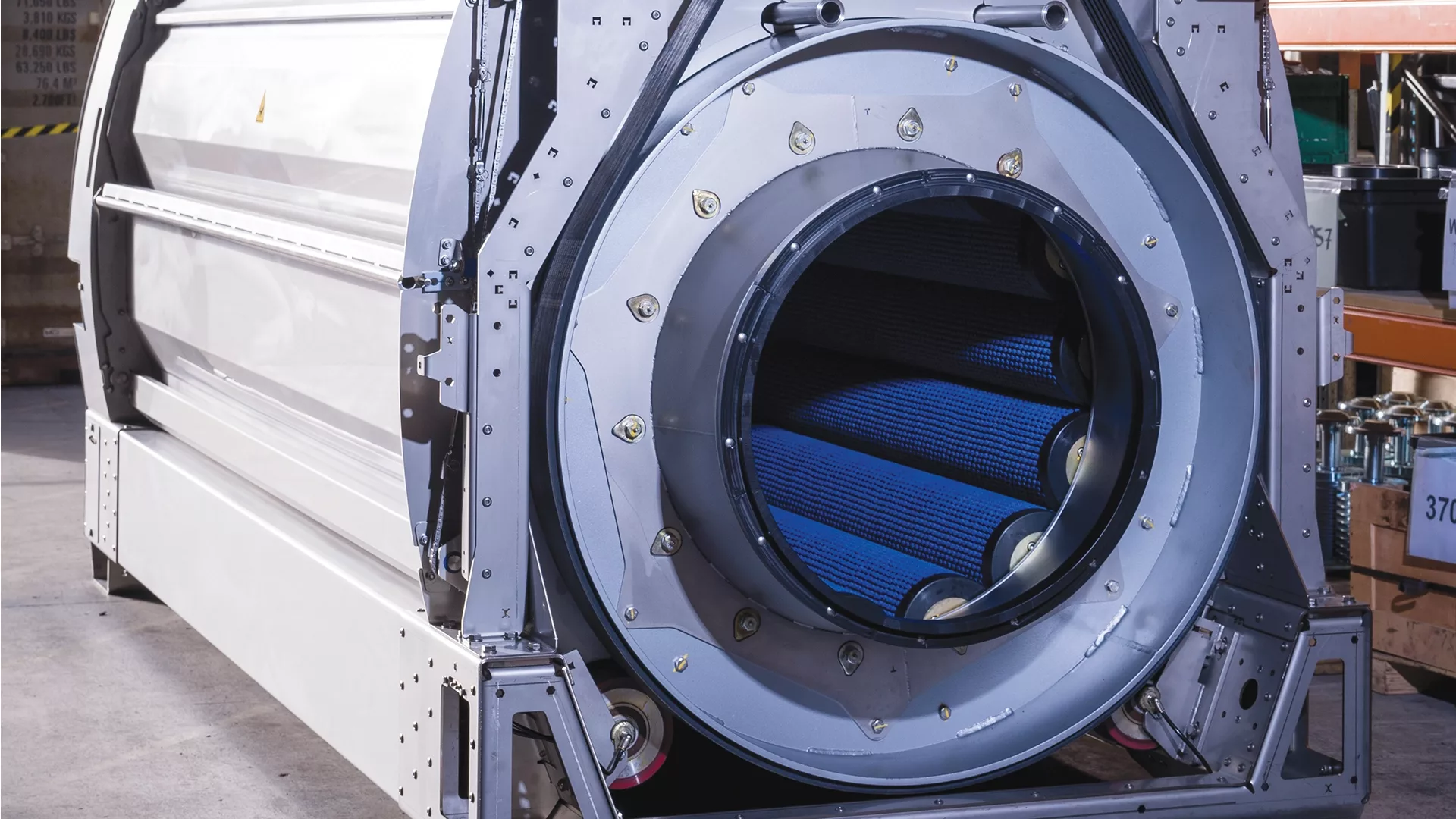

High performance and high efficiency spiral technology.

Automatic carton tunnels providing fast freezing or chilling of meat and poultry products.

The world’s largest horizontal plate freezers with a 24-hour freezing capacity of up to 3,017 cartons.

Suitable for storing and blending liquids, powders and free-flowing solids. Custom-fabricated.

Custom design and fabrication, with extensive experience working on complex, high-end projects.

Leading wide bandsaw technology, with a range of horizontal and vertical resaws for primary and secondary processing.

Large capacity, high performance finger jointing equipment. Horizontal and vertical finger jointers.

Complete line solutions for secondary processors of timber products. Custom designed and built.

Sling sorters, bin sorters and stacker lines for a diverse range of board sizes.

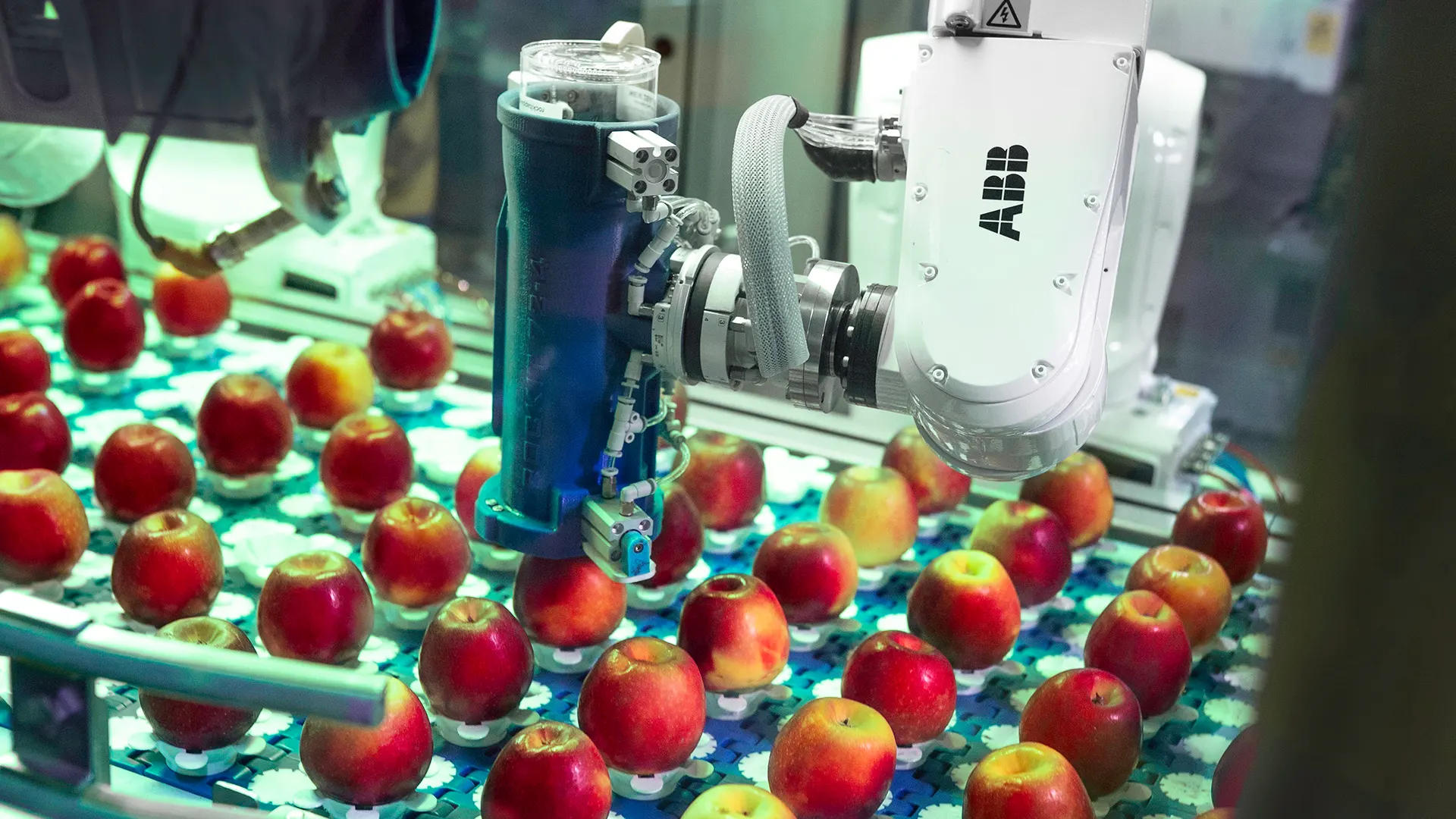

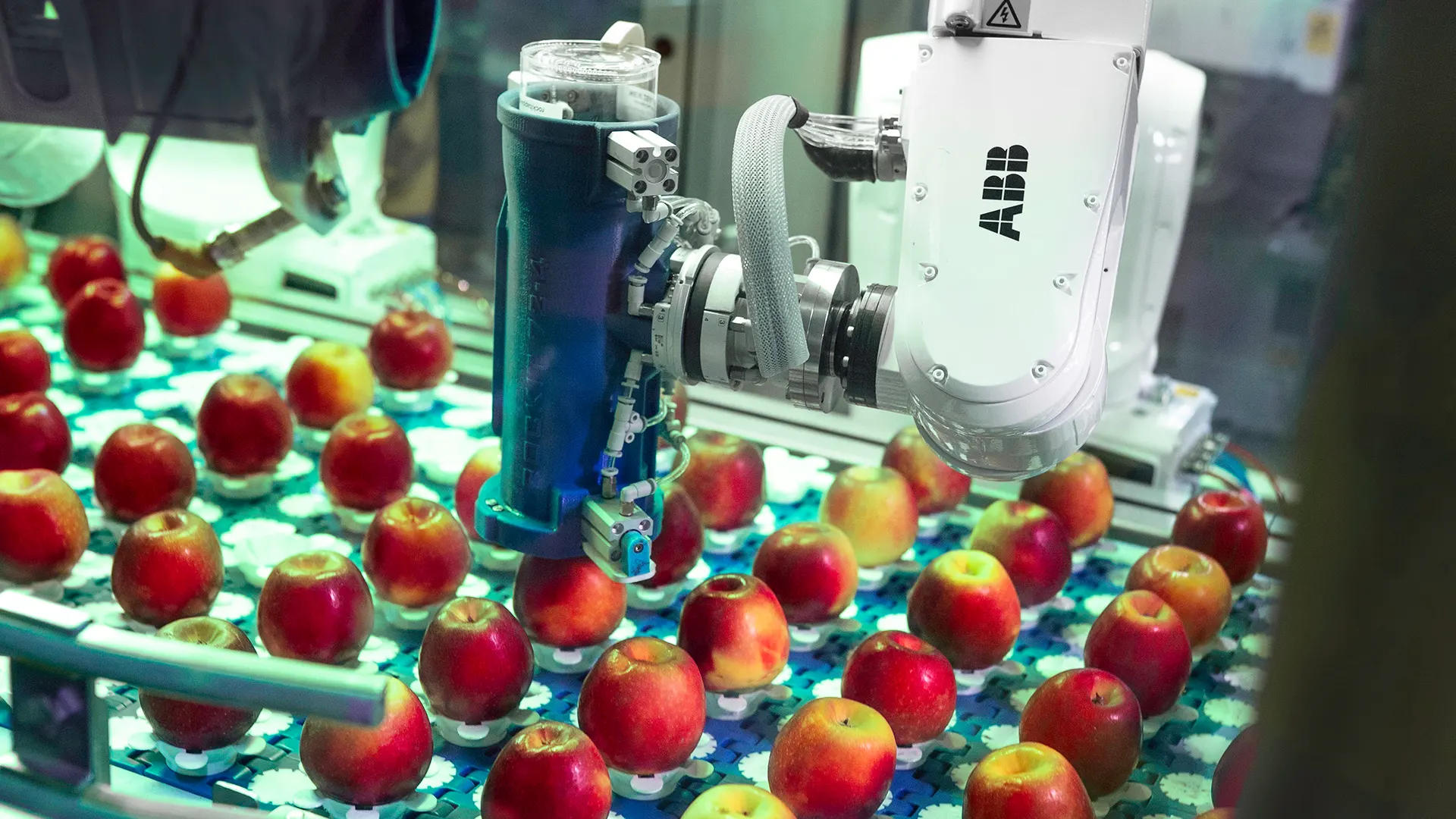

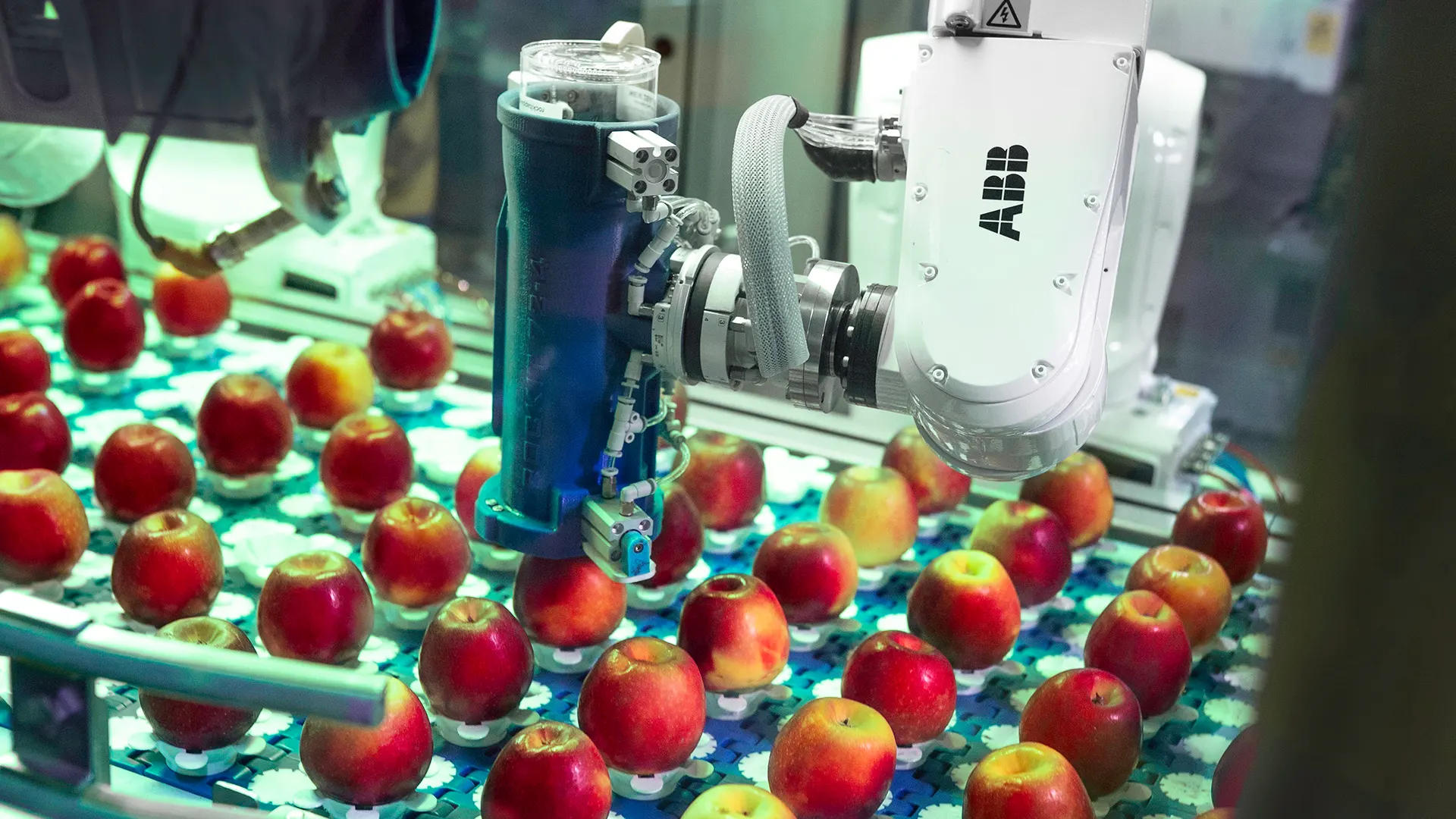

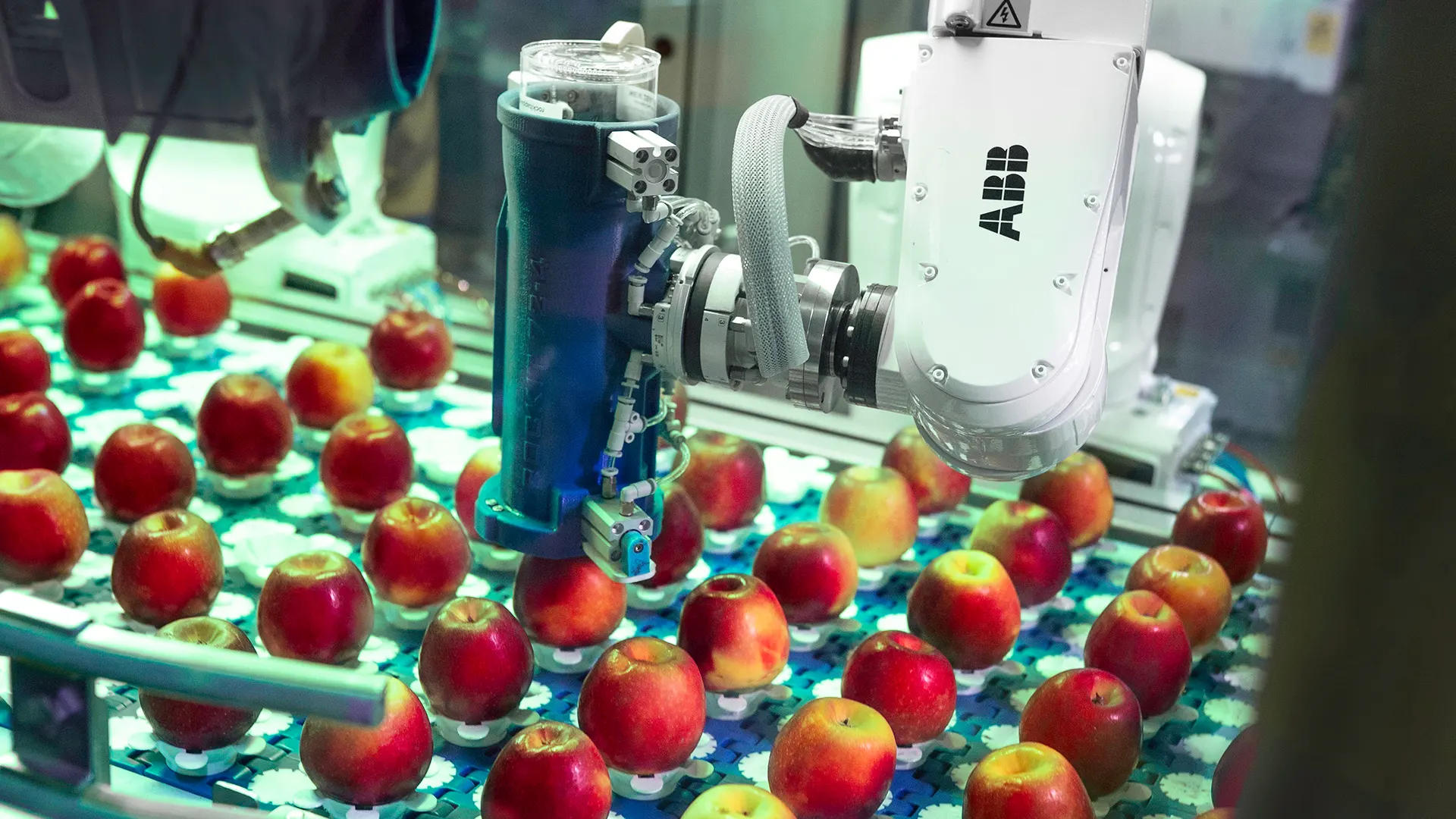

Robotic system to fill tubes with product. Developed for apple packing but could be customised to other applications.

Opens boxes of varying shapes and sizes, without operator intervention. Suitable for hygienic wash down.

Vertical plate freezers, designed to achieve optimal product quality while minimising costs through an efficient freezing process.

A durable and reliable machine for weighing, scanning and labelling. Suitable for hygienic wash down.

Custom-fabricated tanks for fermentation and storage of wine and other beverages.

Vital for storing and managing freshly gathered produce.

Combat food waste with effective post-harvest cooling.

Preserving crop quality and safeguarding equipment.

Automating the packaging and filling processes after harvest.

Elevating crop quality through post-harvest polishing.

Providing a complete line solution.

Where precision, efficiency, and quality converge.

On demand and gentle.

Providing a complete line solution.

Extending the shelf-life of your fresh produce.

In 1998, we acquired AiCo, a brand with a well-established reputation in the industry, a leader in cartoning and packaging equipment for over 35 years.

AiCo equipment is known for its rugged reliability in tough environments and excellent return on investment.

Our range of carton erectors, stuffers, lidders and closers includes specialised solutions for the meat and horticulture industries. We also provide complete line design and integration.

World-renowned as the preferred option for cheese packaging systems, BetaVac was acquired by MHM Automation in 2004.

Hundreds of BetaVac vacuum packaging, testing and turning systems have been installed worldwide for some of the biggest names in dairy.

In 2020, we acquired Mercer, a leading name in the stainless steel fabrication industry.

We specialise in the design and manufacture of plant and equipment for the dairy, wine and food processing sectors in New Zealand and Australia.

Recognised as a world leader in automated reverse packaging and product handling systems, we acquired Haden & Custance (H&C) in 2016.

While many other companies provide solutions to putting product into packaging, we are specialists in removing packaging from product ready for further processing.

Our technologies were developed for the cheese processing and cheese conversion operations but have since been applied to meat processing and e-commerce fulfilment.

H&C equipment is renowned for being robust, reliable and simple to operate, as well as providing an excellent return on investment.

All of our equipment can be provided as standalone machines or as part of a complete process solution. We have particular expertise in the integration of these automated systems into existing process lines.

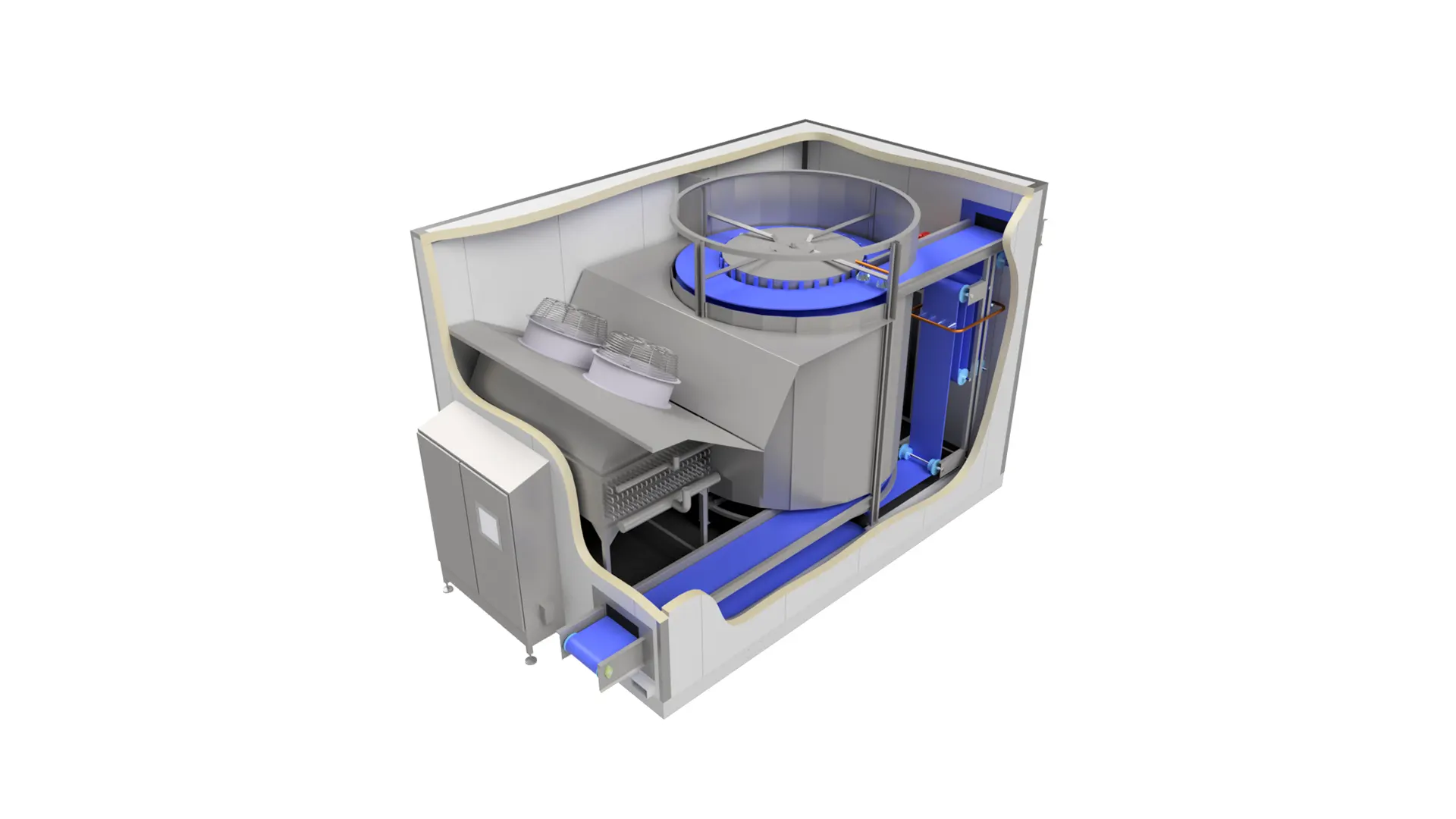

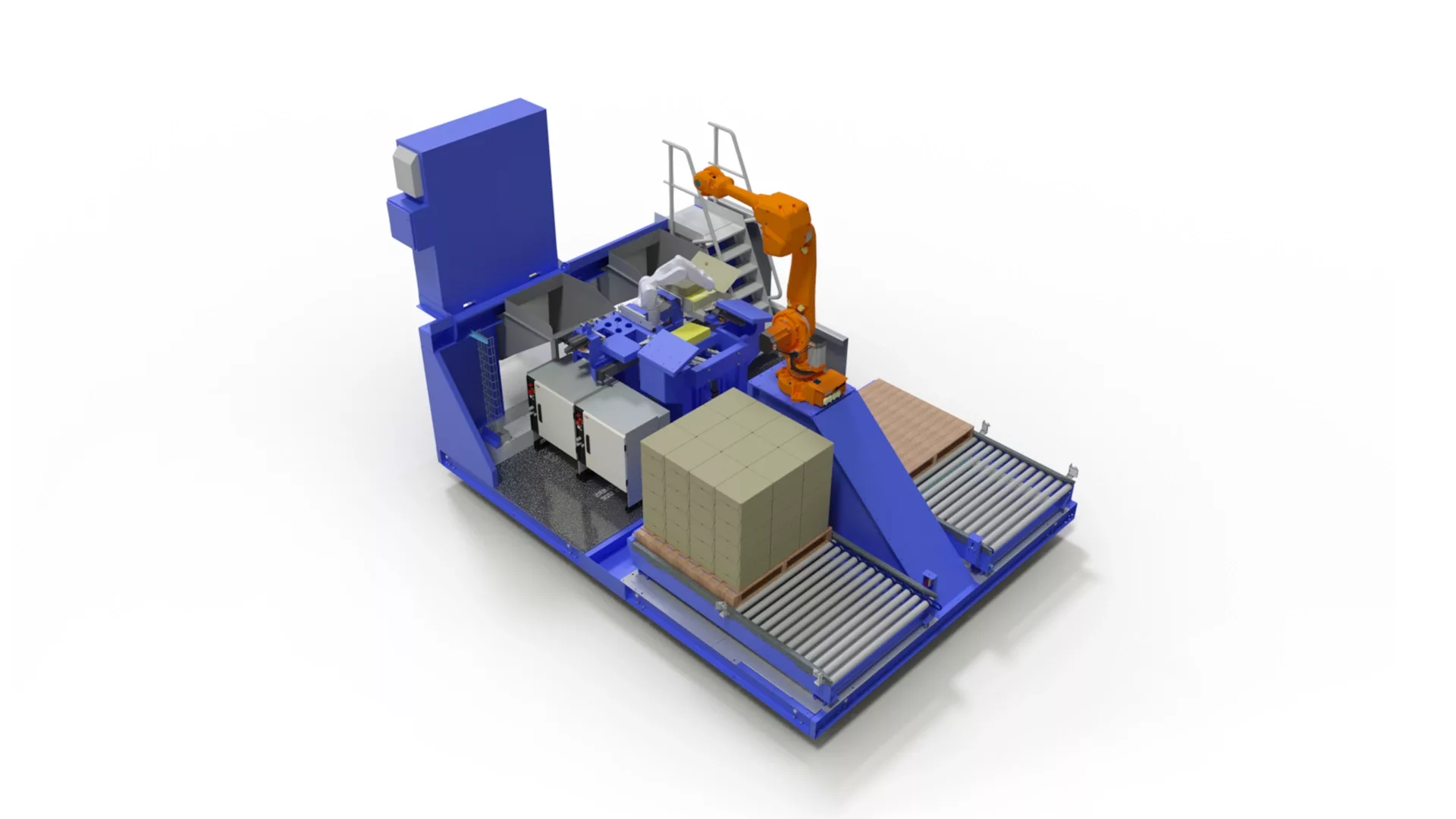

Milmeq, whose automated chilling and freezing systems have established the global benchmark for cooling and freezing meat, poultry and dairy products in cartons or crates, were acquired by MHM Automation in 2018.

Milmeq developed a global reputation for innovation when it introduced automatic chilling and freezing tunnels and plate freezers to the meat and dairy industries.

Since then, hundreds of installations have been completed worldwide for some of the biggest names in meat, poultry and dairy.

Milmeq systems are typically custom designed and installed on-site. We provide a turn-key service from design and manufacturing to installation, commissioning and ongoing maintenance and support.

SCE (Southern Cross Engineering) is well-known for its expertise in designing, manufacturing, installing, and servicing equipment within the meat, dairy, grain, timber, and infrastructure sectors across New Zealand and Australia. In 2021, we completed the acquisition of SCE.

Our technology-led solutions include industry-leading grain stackers, pressure vessels and related boiler systems and timber processing equipment. We also provide heavy fabrication services and have expertise in solutions for agricultural applications and Antarctica.

Wyma post-harvest vegetable and fruit handling equipment is recognised as world leading and used by processors in more than 50 countries. We added Wyma to our portfolio through an acquisition in 2023.

The Wyma product range includes bulk product handling, washing, drying, peeling, cooling, inspection, packaging and more. Complete line solutions are available for processing carrots, onions, potatoes and fruit.

The S-Clave is an innovative sterilisation technology system for surgical devices and instruments.

The system sterilises surgical devices and equipment in a non-porus container that comes out of the autoclave sealed.

The product is revolutionary for the medical sterilisation market with the following key attributes:

We are currently working on the commercialisation of the S-Clave technology in partnership with Atherton, Australia’s leader in sterilisation equipment and infection control products for the hospital, medical and scientific industries.

AGI is a global leader in systems and equipment the agriculture industry, including solutions seed, fertiliser, grain and feed handling for commercial and farm applications.

MHM Automation is the Australasian representative for AGI.

Australian-based Agridry is a specialised manufacturer of dryers for agricultural and food processing operations. It provides mobile and permanent solutions for drying grain and other commodities.

MHM Automation is the New Zealand representative for Agridry products.

Bruks Siwertell is a global leader in wood handling and processing systems, based in Sweden.

MHM Automation represents Bruks stationary and mobile chipping systems in Australia.

Carsoe, from Denmark, is a world-leading manufacturer of stainless steel solutions for the seafood and food processing industries.

MHM Automation represents Carsoe vertical plate freezers in Australia and New Zealand.

Konecranes is a world leader in lifting equipment for manufacturing and process industries, shipyards, ports and terminals.

MHM Automation represents Konecranes products in New Zealand and Australia.

Leadermac is recognised as a world-class manufacturer of four-sided moulders for the timber industry.

MHM Automation represents Leadermac moulders in New Zealand and Australia.

Brazilian-based Omeco is recognised as a leader in the manufacture and supply of equipment for the plywood industry worldwide.

MHM Automation is the Australasian representative for Omeco plywood processing equipment.

UK-based Starfrost provides industrial cooling solutions for the food industry, with particular expertise in spiral freezers and IQF.

MHM Automation represents Starfrost in New Zealand and Australia.

Stenner is internationally recognised as a leader in bandsaw technology. Stenner machinery is renowned for providing high performance over a long service life.

MHM Automation represents Stenner bandsaws in Australia and New Zealand.

Part of the HOMAG Group, System TM is a leading global supplier of customised solutions to the timber processing industry.

MHM Automation is the Australian representative for their finger jointing and complete line solutions.

TGW is an intralogistics specialist with particular expertise in storage and retrieval systems (ASRS).

MHM Automation represents TGW automated storage shuttle systems in New Zealand and Australia.

Calhoun Super Structure fabric buildings is a family-owned business based in Canada. With over 30 years’ experience, they design, engineer, and manufacture leading edge fabric structures.

MHM Automation represents Calhoun in New Zealand and Australia.

Automates the removal of cartons from pallets stacked in random patterns and with multiple carton sizes.

Custom-designed and fabricated storage tanks for suitable for chemicals and acids.

Stainless steel fabrication of sculptures and architectural features for domestic and commercial projects.

High performance ASRS shuttle and elevator system. Suitable for chilled and frozen products.

Safely automate pallet and crate movements, even in a congested working environment.

Prepares bagged cheese blocks for vacuum sealing.

In-line leak detection system for vacuum packed cheese blocks and other products.

Re-orientate products before or after vacuum packing and save space on the production line.

Industry-leading vacuum packaging system for cheese and other products.

Custom designed and fabricated multi-fuel boilers and heat plants.

A complete range of drum and disc wood chippers for low and high throughput operations.

Site-constructed silos, suitable for biogas, waste water treatment plants and aluminium smelters.

Automatically erect cartons at speeds of 10-25+ cartons per minute. Solutions for chilled and frozen product.

Automatically place and seal lids on cartons. Compact machine designed for chilled and frozen products.

A variation of the SRT for cheese processors, providing fast chilling to preserve product quality.

Custom designed conveyor systems for all applications, including in-plant, long distance overland and stockpiling conveyors.

Kettles, pressure cookers, cooking pans, mixing, pasteurising and cooling vessels.

De-palletise, de-box and re-palletise 40lb / 20kg cheese blocks the efficient way.

A complete range of debarking systems, including head, ring and drum debarkers.

Inspects naked cheese blocks for mould and foreign material prior to further processing.

Custom-fabricated dished ends and heads for pressure vessels, tanks and other applications.

A versatile and cost-effective solution for grain storage.

Fast, energy efficient freezing of product in cartons or boxes. 24-hour cycle for 27kg meat cartons.

Affordable and reliable palletising and de-palletising solution, ideal for medium throughput operations.

Achieve high capacity while maintaining gentle handling and minimal maintenance.

Processing solutions for agricultural raw materials.

Standard elevator sizes and capacities as well as customer designs for special applications.

Suitable for a wide range of processing applications, from small to large scale, ensuring minimal degradation.

Drying systems for grain, wheat and other free-flowing products. A full range of mobile and fixed solutions.

Milling equipment for rice milling, pulses processing, maize milling and seeds processing.

Standard mixers and customisable blending systems to suit your commercial or farm applications.

Storage systems that protect valuable grain. Solutions for on-farm and large-scale commercial use.

Industry-leading mobile grain stacker with drive over grid for handling bulk grain and wheat.

Complete solutions to machinery guarding to meet the latest safety standards.

Complete processing for all animal hide products.

Opens boxes of varying shapes and sizes at high speed, for non-sanitary operations.

World-leading crane technology for a broad range of industrial lifting applications.

Handling and processing equipment for large and small diameter logs.

Automatically compact meat in corrugated cartons, to deliver flat boxes for efficient container loading.

Automates the removal of vacuum bags from 20kg / 40lb blocks of cheese.

Removes cardboard cartons from 20kg / 40lb blocks of cheese at a rate of 16 blocks per minute.

Cobots work safely alongside people to automate repetitive tasks.

Custom fabrication of stainless steel benches and features for commercial and domestic applications.

Highly accurate weighing system for dosing micro feed ingredients with precision.

Custom design and fabrication for projects large and small. Specialists in hydro gates and bridge strengthening.

Four-sided timber moulders, from standalone machines to complete auto-planning moulder line solutions.

Automatic carton tunnel that accommodates various product types with different chilling or freezing times.

A full range of equipment for plywood processing.

Custom-manufactured hoppers and storage bins for powders and free-flowing solids.

A patented system for road and rail tankers, providing protection during filling, emptying and transportation.

Stainless steel tanks and tankers for transportation of liquids by road and rail. Insulated or non-insulated.

Automates the removal of vacuum bags from multiple cheese block types and sizes.

De-palletise, de-box, re-palletise and process multiple blocks the efficient way with the Robotic De-Boxing Cell.

Efficient and reliable stacking of boxes onto pallets in high throughput operations.

Screen cleaners and waste conveyors for the intake screens of hydro power stations.

Screens to suit a variety of wood chip screening applications.

Compact palletising and de-palletising system for smaller operations.

Spare parts and after-sales service are available for all products supplied by MHM Automation.

High performance and high efficiency spiral technology.

Automatic carton tunnels providing fast freezing or chilling of meat and poultry products.

The world’s largest horizontal plate freezers with a 24-hour freezing capacity of up to 3,017 cartons.

Suitable for storing and blending liquids, powders and free-flowing solids. Custom-fabricated.

Custom design and fabrication, with extensive experience working on complex, high-end projects.

Leading wide bandsaw technology, with a range of horizontal and vertical resaws for primary and secondary processing.

Large capacity, high performance finger jointing equipment. Horizontal and vertical finger jointers.

Complete line solutions for secondary processors of timber products. Custom designed and built.

Sling sorters, bin sorters and stacker lines for a diverse range of board sizes.

Robotic system to fill tubes with product. Developed for apple packing but could be customised to other applications.

Opens boxes of varying shapes and sizes, without operator intervention. Suitable for hygienic wash down.

Vertical plate freezers, designed to achieve optimal product quality while minimising costs through an efficient freezing process.

A durable and reliable machine for weighing, scanning and labelling. Suitable for hygienic wash down.

Custom-fabricated tanks for fermentation and storage of wine and other beverages.

Vital for storing and managing freshly gathered produce.

Combat food waste with effective post-harvest cooling.

Preserving crop quality and safeguarding equipment.

Automating the packaging and filling processes after harvest.

Elevating crop quality through post-harvest polishing.

Providing a complete line solution.

Where precision, efficiency, and quality converge.

On demand and gentle.

Providing a complete line solution.

Extending the shelf-life of your fresh produce.

© MHM Automation| Website by Naked Creative